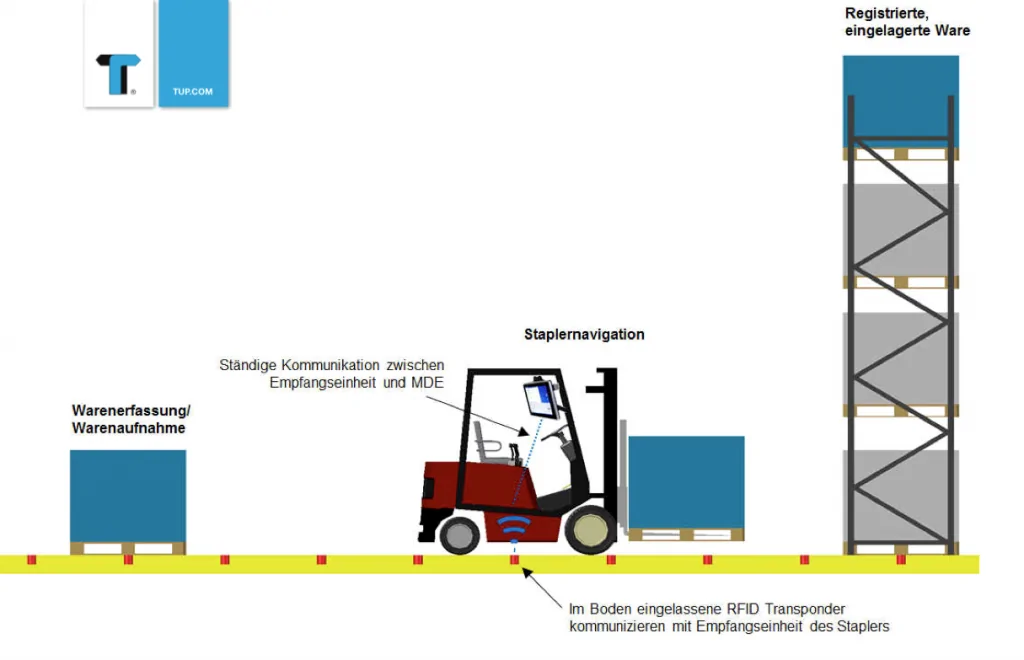

Forklift navigation with RFID

Using so-called transponders(RFID tags), which are embedded in the floor at predetermined intervals (grids), RFID technology makes it possible to localize goods and navigate vehicles. One example is forklift truck navigation. It is therefore also possible for the forklift truck to store goods in a designated area that is also equipped with transponders. If the goods are stored on the shelf, a height sensor on the lift truck ensures that the storage height (shelf height) is automatically set beforehand. A further load distance sensor in turn recognizes that the goods have been unloaded correctly (source: Still).

The passive RFID tags embedded in the floor communicate with a special receiver unit on the forklift truck. This is permanently installed on the transport vehicle and describes a so-called RFID high-frequency module, which can constantly receive, process and send information. Received information is automatically transmitted to the driver via a small terminal. In most cases, information is transmitted via WLAN.

Two variants of forklift navigation

There are two variants of forklift navigation. On the one hand, the forklift truck can be navigated using RFID technology and additionally guided by a person. The other is navigation without personnel. If navigation is carried out without additional personnel, the driverless transport systems are equipped with specific sensors for safety reasons. They scan the surroundings during the journey and stop automatically as soon as people or objects come too close to the route.

In future, manual counting, scanning, recording and checking processes, which can be simplified with the help of RFID, will also be replaced by these transponders, which are roughly the size of a match.

You can find more information on this topic under RFID transponders.

Image source teaser image: © Kadmy – Fotolia.com

Graphic in the text: © tup.com