Efficient structures through sustainable cost reduction – Part II

If processes within the company are continuously analyzed and thus optimized, not only are new synergies created, but the resulting structures also lead to demonstrably sustainable cost reductions. The following second part, ‘Efficient structures through sustainable cost reduction’, shows why a target-oriented process analysis is so important.

Identification of potential and prioritization

The first step is to carry out an analysis of potential. This can be carried out in three stages with the help of process benchmarks:

- Selection of product groups

- Potential assessment in the process, at product level and at system level

- Prioritization and selection

This brief and concise analysis of potential has now identified, evaluated and selected the complexity drivers, waste and potential within the entire value creation process. The prioritized potentials are raised, for which concepts for realization are created.

Concepts for raising potential

Depending on the scope of the task, two to five concepts can be developed for the respective task areas. The level of detail of the concepts is also highly dependent on the complexity of the task. It can be helpful to separate the concepts into technical and implementation concepts. As a rough guide, the following aspects must be included in the concepts:

- A clear definition of the objective,

- the prerequisites/optimizations in the material and information flowto leverage the potential (framework conditions),

- the specification and definition of the changes to be made in the system, process or product,

- ensuring sustainability and

- a business and monetary evaluation.

- Once the concept variants have been created, they must be evaluated and selected – similar to the evaluation system for selecting potential.

Cost reduction: realization of potentials

Once the technical and implementation concept has been selected, its implementation must be driven forward. Three areas can be identified that have an influence on the successful realization of potential. These include

- Implementation

- Management

- Qualification

Two types of optimization measures occur during implementation: process-oriented and system-oriented optimizations. It is important to make a clear distinction here and to differentiate the implementation procedure, especially with regard to the selected efficiency enhancement strategy. Process-oriented optimizations are usually quick and easy to implement. This includes so-called quick wins, which represent selective improvements to existing processes. System-oriented optimizations have a predominantly medium to long-term character. This means that the conversions are fundamental changes to the status quo, such as the introduction of a customer-supplier principle. Such optimizations require a lengthy change process within the entire organization.

Sustainability monitoring and coaching

Once the defined optimizations have been integrated into the system, a final support phase must follow. The most important aspect in this part of the optimization project is ensuring sustainability.

Conclusion – cost reduction

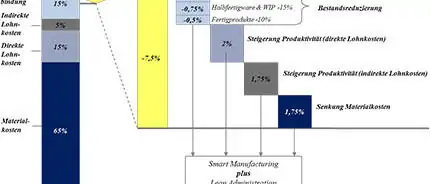

Efficient structures and processes are the basis for competitiveness on international markets. The focus here should not only be on optimizing production or individual areas. Instead, an end-to-end view of the entire value chain and the associated interfaces identifies the greatest potential in direct and indirect areas. This should take place at the three levels of the company: system, process and product. However, soft factors also play an important role in efficiency improvement projects. The successes that can be achieved in a holistic efficiency improvement project are often substantial and are of the following magnitude:

- Reduction in throughput time across the entire process chain of between 30-70%

- Increase in productivity by up to 30%

- Increase in throughput by 10%

- Reduction in inventory value by 30-50

- Increase in delivery reliability by 25%

- Reduction of process costs by 10-25

- Reduction of material costs by 20%

You can find the first part of this article under Efficient structures through sustainable cost reduction – Part I

Image source: Wassermann AG