Efficient structures through sustainable cost reduction – Part I

Due to ever more rapidly changing market requirements, companies are facing major challenges – an enormous increase in the number of variants. This leads to a high level of complexity at product and, above all, process level. The result is an increase in manufacturing and overhead costs as well as a high demand for flexibility and reactivity. Under- or overcapacities lead to a far-reaching intensification of these effects.

In addition, increasing competition leads to a need for action on international markets. In practice, competitiveness is largely determined by two factors: efficiency within the organization and the product. It must be made clear that the product is the main driver of the company’s processes and has a major impact on the system. Two fundamental questions must therefore be considered in order to increase competitiveness within a company:

- How efficient is the company’s organizational structure or process organization and therefore its value creation, management and support processes?

- To what extent does the product meet customer requirements, especially in comparison to the competition, and what complexity is created as a result?

Basic strategies for improving efficiency

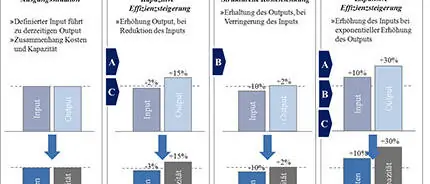

To improve efficiency, a company has three different strategies that consider two characteristics or ratios:

- Input versus output and

- Costs versus capacity

1) Increasing capacity efficiency

The capacitive increase in efficiency is concerned with increasing output and thus capacity while maintaining the input or cost structure and has a capacitive background.

2) Structural cost reduction

Structural cost reduction aims to increase efficiency with a focus on cost reduction. A significant reduction in overheads and production costs defines clearly quantified objectives. A lack of or even negative economic growth and market-side sales weaknesses are common framework conditions.

3) Expansive increase in efficiency

Expansive efficiency enhancement has a growth-oriented focus. It increases the company’s efficiency by increasing output or capacity while at the same time achieving disproportionately low growth in input and therefore costs.

The choice of focused strategy is very much dependent on external and internal influences on a company, such as

- Market growth,

- Market position,

- economic situation (liquidity) and

- strategic orientation of the company.

Common optimization concepts and their effectiveness

Against the background of the strategies outlined above, lean production and lean administration are praised in the industry as overriding “saviors”. Optimization measures and design principles using the methods and tools of the aforementioned focus areas bring far-reaching improvements in process and product costs. However, the greatest potential lies in the interfaces between the company’s organizational units, which can only be identified by taking a holistic view of the entire supply chain.

The challenges lie in the implementation

Potential can often be easily identified, but many companies face a challenge when it comes to implementing the identified potential. This is due to inadequate change management and therefore insufficient sustainability of the processes introduced. A practice-oriented approach to such problems actively involves the employees.

The road to success: a holistic and employee-oriented approach

The establishment of a standardized procedure within the company is the basis for success. The focus here must be on the core or value-added processes. Starting from this, management and support processes can be considered. The interfaces within the organization should be at the heart of this approach.

The second part of the article can be found under Efficient structures through sustainable cost reduction – Part II.

Image source: Wassermann AG