A digital twin is an image of a real object or process in a virtual/digital space. In this type of modeling, digital twins are formed from data and algorithms. They can be supplied with historical and real-time data using sensors, thereby connecting them to the real world. The real object is also referred to as an asset, which may or may not already exist. A digital twin can thus also represent a real object in the future.

Differentiation from simulation

Digital twins can achieve a very high degree of complexity and at the same time have intersections that make a clear definition difficult. For example, at first glance, a digital twin may appear to be a 3D model or an ordinary simulation. However, there are significant differences and distinctions in what a digital twin can do.

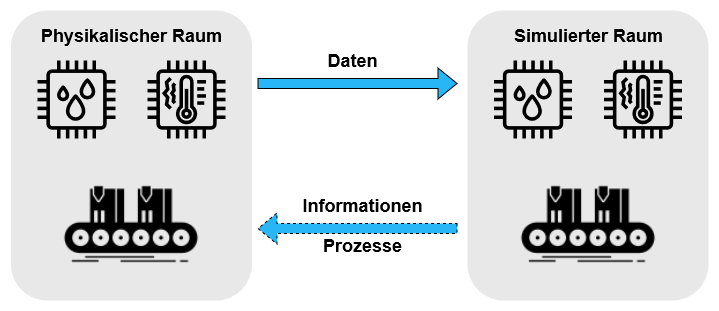

A digital twin can be fed not only with historical data, but also with real-time data. Furthermore, it not only receives and processes the data, but also feeds it back to the real object, since it is networked with it. Thus, a digital twin represents an extensive virtual environment in which individual simulations can be carried out. Through the real-time data and the connection with the real object, a digital twin has an information flow that runs in both directions: to the real object and from the real object to the digital twin, creating a constant feedback loop. This allows problems to be examined from multiple perspectives and in a much larger number – something that conventional simulations cannot do.

Why digital twins?

Digital twins are used to visualize processes for simulation, production, analysis and development. In Industry 4.0 and digitalization in general, they form a kind of foundation by accompanying entire cycles of products or services in development and production. This allows the respective processes to be optimally planned and adapted.

What is needed is a real object, a virtual space and various data about the respective conditions of the environment. Descriptive algorithms and real-time data are used to create the digital twin and map it in a virtual display space. A digital twin can also be composed of several other digital twins. For example, the digital twin of a production line consists of the individual production machines and the product itself, the continuous material handling system for the supply of parts and the industrial trucks. In cases such as the mapping of an entire production plant, the composition is often divided into three types of individual twins. These individual digital twins can have different forms or focuses and can thus differ fundamentally from one another.

This is briefly explained schematically below:

- The twin of the end product can be a CAD or 3D model, for example,

- while the programs, tools and machines form another type of digital twin or level of the end product,

- just like those digital twins that use key figures on production and production times as well as on quality and delivery times to simulate performance and execution in particular.

The more complex the design of a digital twin, the more data is generated and processed. Accordingly, big data and the respective techniques and applications in the context of digital twins appear frequently.

Fields of application for digital twins

Production technology is the area where digital twins are primarily used because it can be used over the entire life cycle of a product and enables continuous optimization. In the design and development phase, it makes the laborious and costly construction of prototypes obsolete, while during the manufacturing phase, it helps to improve the quality and efficiency of the respective processes. The digital twin also analyzes the usage phase and the increasingly important recycling phase, running simulations for each.

In intralogistics, a digital twin of complex materials handling technology can be used to improve its efficiency in physical space.

In practice, for example, new components from suppliers can be tested using digital twins without the need to deliver and install real components. These types of tests can be carried out in a much shorter time and with less effort, and on a much larger scale. This accelerated analysis of many different components makes it possible to quickly find the optimal component or to exclude unsuitable parts.

In addition, digital twins are increasingly being used for objects that are either systemically relevant or on which human lives depend, such as wind turbines or aircraft turbines. Buildings with complex structures and processes, such as hospitals, often have a digital twin as well.

Digital twins are also used across companies, although this requires the creation of interfaces and a certain amount of coordination regarding the digital models.

What are the advantages of digital twins?

The more complex a digital twin is, the more areas it can analyze and simulate. Consequently, the number of specific advantages that the digital twin brings with it also increases. In general, the following advantages can be identified:

- Facilities and processes can be optimized as early as the planning phase, even before the first real product comes off the production line. This ensures smooth implementation and error-free operating processes right from the start.

- Development and production benefit from enormous time savings, which results in shorter development and production cycles and thus makes new products market-ready faster.

- The real-time data from the real object provides a holistic view of the facilities and products; in addition, meaningful forecasts can be made when certain parameters change. In intralogistics, for example, the verification of the acceptance of an urgent order would be one such case, which is carried out by a digital twin. The digital twin simulates this rush order and its effects on the entire operating performance, as well as on the products, machines and services affected, and on personnel deployment. Such orders, which can disrupt and confuse normal operations, can be run through as often as you like and in a wide variety of constellations using digital twins. Not only for specific, current cases, but also for hypothetical, future ones.

- The depth of understanding of the individual processes and their entirety increases significantly with the digital twin, because the knowledge gained from the virtual space is so immense.

- Cross-company coordination is faster and easier because the digital twin provides data that comes from the virtual space but is valid in the real environment and for the real objects.

- Within a company, a digital twin also serves as a single source of truth for all departments and individuals involved. This facilitates both communication and organization.

Summary

The forms that a digital twin can take are so diverse that it is not always possible to clearly define and distinguish between them. A digital twin can represent a product, a large machine, a service, an individual process, an entire building – or all of these things together. What is crucial is that the digital twin is the virtual representation of a real object in a virtual space and is supplied with real-time data from the real object, which is usually done by sensors (keyword IoT). However, a digital twin can also access historical data. The main difference to a simulation is that a digital twin is connected to the real world, the real object.

All of this enables the digital twin to identify problems and challenges and, if necessary, solve them (virtually) before they arise. In a production process, this means that individual components can be tested, new product features can be checked and changes in framework conditions, such as new laws and standards, can be efficiently implemented. A digital twin is therefore able to accompany a product throughout its entire life cycle, always enabling the optimal decisions and modifications to be made in a resource-efficient manner.

The more digital an environment becomes, the more digital twins will be used, as they have analysis, monitoring and forecasting capabilities that are far superior to other technologies and methods. However, the use of digital twins is not always useful, as it is also a question of cost. Suitable scenarios are characterized by degrees of complexity that only a digital twin can meet, and in which sufficiently large amounts of data can be measured, collected, evaluated and processed by the digital twin on an ongoing basis.