The goal of logistics solutions is to optimize business processes in warehouses and distribution centers, to reduce costs, and to prepare the accruing data appropriately for further optimization. If this is no longer the case, or if this objective can no longer be met, the replacement of warehouse management systems, hardware or software packages in use is on the agenda.

There are many reasons for initiating this process. What they all have in common is that the need to do so is quite urgent before a replacement is considered. Common scenarios on the market are the following:

- Missing functions that stand in the way of further growth or ongoing optimization

- Lack of integration with the distribution center or connectivity to upstream and downstream systems

- Changing or higher performance requirements that are no longer met by existing systems

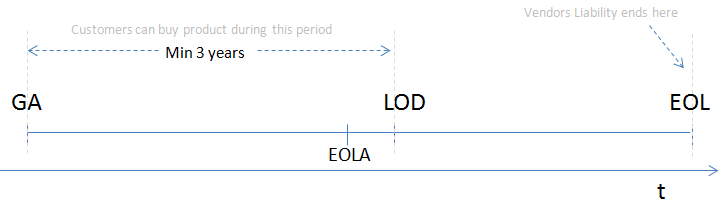

- The vendor does not continue to develop the system or the deployed solution is a discontinued or EOL product

- For vendors with high staff turnover, the constant onboarding of the contact person or the resulting stalled processes can also be a reason for switching

The expectations and risk potential of replacement processes are high: On the one hand, a significant improvement must be achieved to justify the investment and the associated disruption to regular processes. On the other hand, unpredictable downtimes, possibly necessary rework as well as time and budget overruns can quickly tip the cost-benefit calculation.

The need for a replacement arises primarily where software is thought of as a product and thus follows the classic product life cycle.

However, if the software is understood not as a product but as a service that supports business processes, things look different: A recurring, risky replacement process is made obsolete by this approach.

Solution-oriented value creation via continuous integration

The first thing to do is to escape the old cycle. The key is to replace a big step from solution A to solution B, as usually happens during a replacement, with many small steps. Instead of a big bang, the existing software must be adapted gradually. However, this also requires parting with intransparent software monoliths – especially in business areas where the potential for innovation and change is high.

However, moderation and common sense are always paramount. Packaged software remains a valuable part of enterprise portfolios. After all, non-business critical systems or those that have no impact on the business model are perfectly suitable for product solutions. In addition, many companies have already made large investments in financial and other modules within their ERP solution. It would be wasteful to convert these to continuous integration, especially if the business is not focused on financial services. The same is true for a variety of HR packages and email clients.

Don’t let third-party business models dictate business processes

The big weakness of software packages, however, is version dependency. The vendors of these packages usually follow the business model of producing new versions with many features, functions and performance improvements over the previous version. Once their customers receive the new version, they begin to modify it to fit their own business processes. Modifications away from the standard package are critical for users, especially in ERP solutions: rarely does software reflect a company’s business model 100 percent. Any customization outside the standard package makes it very expensive to upgrade to the next version because the customizations have to be integrated again.

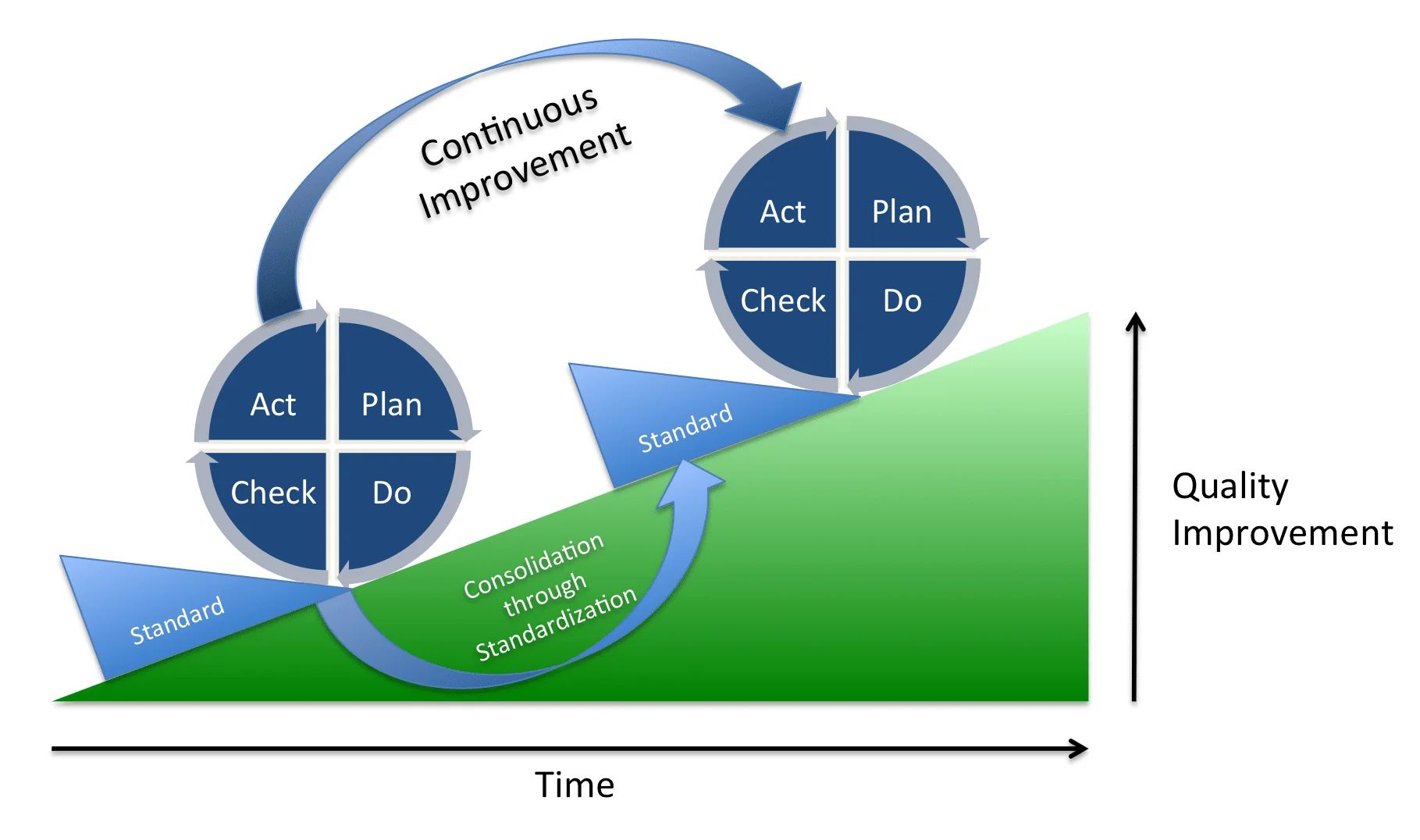

Implementing individual functions is the antithesis of packaged software. The key advantage of software built on the principle of continuous integration is that one feature at a time can be designed, developed, tested and integrated. This helps ensure quality and timeliness without ever replacing a complete software package. As an added bonus, users can easily learn new features because the software does not radically change in one fell swoop.

In the logic of continuous integration, the business processes are the pacesetter. The goal of this type of software development is to avoid dependencies, which enables high flexibility, reaction speed and thus resilience. Through open standards, fast update cycles and the highest possible degree of independence from ready-packaged solutions, business processes are not supported by the best possible assumption of a third-party provider, but by the concrete requirements of those responsible within the company. In this way, Big Bangs in both a positive and negative sense become many small, highly customized and less risk-prone steps that follow the Plan-Do-Check-Act model. Version replacements become simple function additions and the software no longer needs to be replaced in the true sense, but only extended or adapted.

Intralogistics must be able to adapt quickly to seasonal fluctuations, social trends and political developments. Only in this way can it become a competitive advantage. That’s why we rely on modular, combinable software modules that we continuously update and customize for each of our project partners. Through our guiding principle “software follows function” and the clean architecture principle, we create an antithesis to standardized package solutions, which often only receive new features or adaptations through far apart version updates. Our focus on business processes and software modules enables our project partners to react quickly, flexibly and, above all, securely to changing conditions in their respective markets, whether in the fashion, automotive or pharmaceutical sectors – without the wheels ever coming to a halt.