Lean method Heijunka

The Japanese lean method Heijunka promotes production in which the production flow of the parts market in particular is guaranteed throughout, despite market fluctuations. Transportation and idle times are avoided and materials are distributed across the entire production process; bottlenecks in replenishment are taboo.

The origin of Heijunka

The Heijunka lean method was developed in the 1950s by Toyota production manager Taiichi Ohno and forms the basis of the Kanban and just-in-time production methods. At the end of the 1940s, Toyota was only able to assemble vehicles at the end of the month because it had enough production parts available. Therefore, the prerequisite for production planning according to Heijunka’s principle is a forecast of the products likely to be sold in the next periods.

Market analysis

Taiichi Ohno was already aware at the time that a detailed and long-term analysis of the market would provide the necessary data for an accurate forecast – as in the past, customer orders, past sales data, studies on related industries and general market research measures (surveys, market analyses) are used today. Once the planning is in place – usually a period of one to three months is chosen – spare parts/production-critical components, for example, are kept in stock as a precautionary measure to absorb the aforementioned fluctuations in demand.

Retrofit and other optimizations

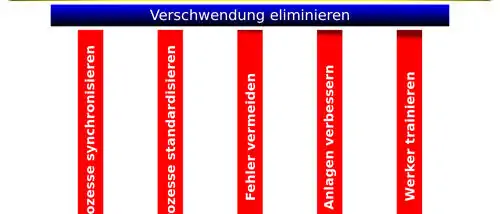

In order to successfully implement Heijunka, a kind of retrofit (optimization) of the production facility is essential. Machines and the material flow itself must withstand an economic test and, if necessary, be adapted to production according to Heijunka – the production material must flow through the production process without large intermediate storage, batch sizes must be reduced (ideal: batch size 1). Human labor is also included in the planning. This is the only way to take account of the trend towards the manufacture of individually configured products (contract work).

Pull principle

For a functioning Heijunka, planners and logisticians use the pull principle. The customer places the demand with the manufacturer, who then initiates production. Each production unit (process section) reports to the previous unit what it needs to meet this demand.

The result of the Heijunka lean method: the respective production section produces what was ordered in line with demand. The aforementioned forecast/market analysis for up to three months therefore helps to harmonize or level out production and stock in the long term.

Further information on the topic of lean can be found under Lean Administration Part 1 and Lean Administration Part 2.

Image source: © Kanban Consult GmbH / License: CC-by-sa/2.0