Automatic volume recording of parcels and pallets

For efficient storage space and shipping optimization, the size (length, depth, height) and weight of a carton or palletized unit load is determined by automatic volume recording at goods receipt. If required, the individual products can also be recorded by volume.

Automatic volume recording is used to record the master data, which in turn is divided into article master data, customer master data and supplier master data, which is then managed by the host/ERP system. On the one hand, the volume recording serves to complement the individual product-specific information, and on the other hand, the packing department can allocate the appropriate cardboard packaging for the order based on the recorded article dimensions. The dimensions mentioned are also necessary for storage in order to make the best possible use of warehouse capacity. However, the recorded dimensions are also relevant for extra logistics, for example for loading a truck.

Practical example: automatic volume recording

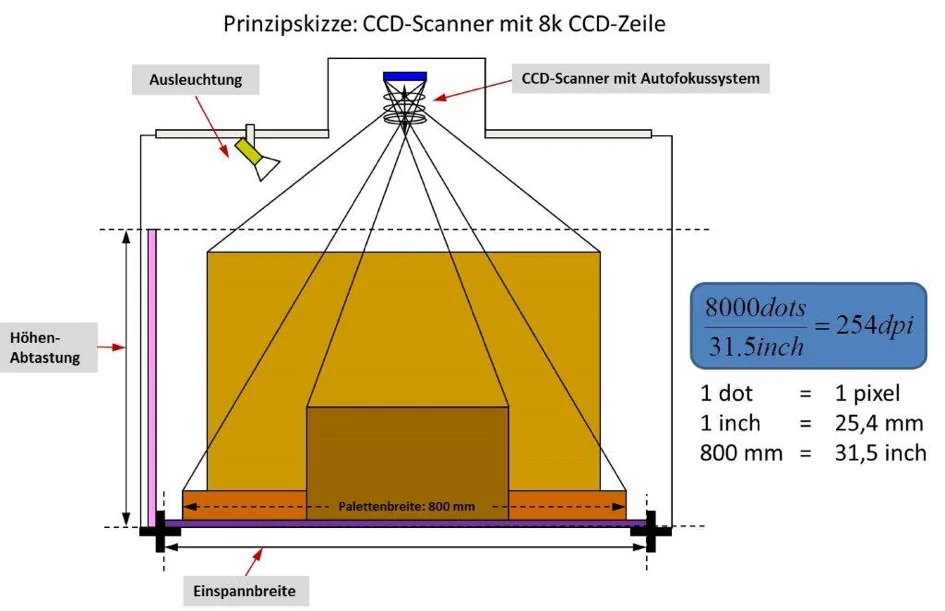

In the first step, the barcode attached to the outside of the goods by the supplier (e.g. GS1) is scanned and the volume is recorded using sensors. For this purpose, the edges of the package or pallet are scanned; modern scanners also create a 3D depth image. During the measurement of the edge areas, the respective object is also weighed. The recorded information is assigned as master data to the item and the existing data records and transferred to the ERP system above. Depending on the system, automatic volume recording takes just a few milliseconds.

For more information on the detection of goods, see The further development of CCD cameras and Bulk detection in extra- and intralogistics.

Image source cover picture: © VRD – Fotolia.com

Image source contribution image: © tup.com