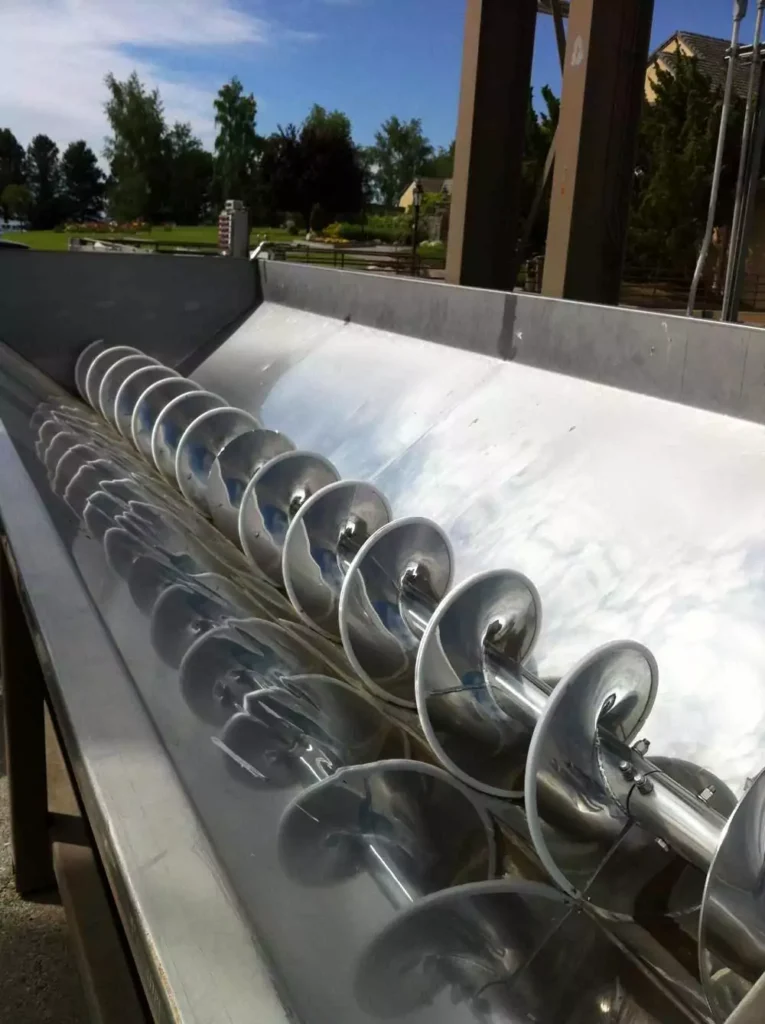

Transport systems are needed in warehouses to transport goods. For this purpose, there are a variety of options in materials handling technology for different requirements. In addition to roller, vibratory and circular conveyors, screw conveyors (also known as Archimedes spirals or conveyor spirals) are also continuous material handling systems. Continuous material handling systems are characterized by the fact that goods are transported in a continuously generated flow. In a screw conveyor, goods are transported by a rotating screw, which is often made of steel. They flow through a tube, which is often flexible, from one or more pick-up points to one or more delivery points. A screw conveyor transports the corresponding material horizontally, vertically or at an angle over several meters.

The screw conveyor is designed in such a way that a screw conveyor is driven in a trough and the material to be conveyed is fed in and out at the corresponding inlets and outlets. In contrast to a spiral conveyor, the screw conveyor has a screw shaft in the middle.

Screw conveyor and how it works

Gravity and the friction of the transported material on the so-called trough walls ensure that the material does not rotate with the screw, but is permanently transported further. The effectiveness and efficiency of the transportation depends on the filling level, which must not be too high, otherwise the friction on the wall is too low. An important criterion for vertical transportation is the speed, because it generates the necessary centrifugal force that makes friction possible in the first place. This requires high speeds of 250 to 400 revolutions per minute (min-1). This is also referred to as the so-called rotational frequency. By way of comparison: a helicopter’s main rotor usually reaches a speed of 400 min-1, whereas a diesel engine reaches around 5,000 min-1 (source: Wikipedia).

A screw conveyor is a materials handling system that, as mentioned above, transports goods according to the principle of the Archimedean screw. The image of a materials handling system with a flexible screw is intended to make the way a spiral conveyor works clearer. The suction pipe of a screw conveyor can be used as a funnel thanks to its U-shaped loading chute.

Principle of a double-lead screw conveyor, also known as an Archimedes spiral

The material to be conveyed flows from above into the loading chute through the flexible conveyor spiral. The spiral centers itself automatically within the tube. There is a small gap between the spiral and the tube wall. This allows goods to flow through the screw conveyor without damage and prevents the material from being crushed or scraped.

With flexible conveyor spirals, goods can be conveyed quickly and evenly at a high speed by a flexible spiral. The conveyor screw is usually driven by a motor. The tube in which the spiral is located is usually made of plastic or steel. Goods can also be transported in rigid tubes. In contrast to flexible screws, there is no bend in the tube with rigid screws. A rigid screw therefore has a less flexible effect on the use of space.

Screw conveyor inside a half-closed trough. (Image: Agne27 /CC BY-SA 3.0

Continuous material handling systems are mechanical, pneumatic and hydraulic conveying devices that move the material to be conveyed from the loading point to the unloading point at a constant speed, at varying speeds or in cycles. They are stationary, mobile or movable and are used to convey bulk materials or piece goods.

DIN 15201, T1

During the diagonal, vertical or horizontal transportation, further processing steps such as portioning, mixing, draining, compressing, cooling or drying can also be applied in parallel. The conveying capacity is determined by the speed of rotation, the internal and external diameters, the pitch, the degree of filling and the friction of the material being conveyed on the screw conveyor. The maximum conveying capacity is achieved when the friction at the screw conveyor is low compared to the friction at the trough wall.

Important: The decisive factor in the design of a screw conveyor is the expected degree of filling over the process length. The pitch of the screw and the channel depth are the main factors in calculating the filling level; the larger the pitch, the higher the filling level.

Screw conveyor and its designs

Depending on the application and product properties, there are single-shaft and twin-shaft screw systems. Twin screw conveyors are mainly used for continuous mixing and crushing. Spiral conveyors are generally used when the vertical, horizontal or inclined conveying path curves.

Well-known screw conveyor designs are:

- solid screw

- band screw

- agitating screw

- paddle screw

Conveying lengths of a few meters are just as common in practice as conveying lengths of over sixty meters, which are realized by intermediate bearings. A special feature is the geometry of extruders and meat grinders. There, the helix is designed so that the cross-section narrows towards the outlet, creating high pressures that press rather viscous material through templates or into molds.

Use

Screw conveyors are particularly suitable for conveying liquids, granulates and powders and are used, for example, in grain silos or in the production of pellets. They also play an important role in the production of plastics, where they are known as extruders. Plastic pieces are then pressed out at the end, just as coarse pieces of meat are processed into minced meat in a meat grinder.

Screw conveyor summary

A screw conveyor is used, for example, to transport bulk material. The screw conveyor is rigid and fixed in place. It consists of rotating screw-shaped conveyor screws that move within a trough or tube. “As a modification of this most commonly used standard design, the conveyor screw can also be designed with a double helix, conical helix or helix with variable screw pitch. Special forms are the paddle screw, in which the helix is replaced by individual paddles, the ribbon screw, in which the screw helix is designed as a ribbon attached to the shaft with webs, and the spiral conveyor, in which the shaft is missing [VDI 2330]. The spiral conveyor is also known in a flexible design [Kun-1983, Sch-1989a]. Another special design is the screw conveyor. In this case, the spiral is attached to the conveyor pipe, which now rotates. Screw conveyors are particularly in demand in the plastics, food and building materials industries. This is because they are particularly suitable for transporting goods that are difficult to convey, such as food or bulk materials.

Stefan Rakitsch, Dimensionierung und Auslegung stark geneigter Schneckenförderer / Dissertation / Seite 2

Teaser image: Chong Fat / public domain

Archimedean spiral: Author: Silberwolf, Image license: CC-BY-SA-2.5