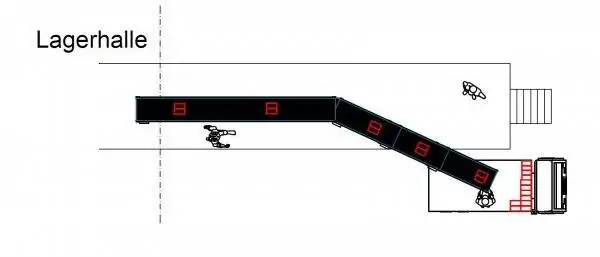

Single and double telescopic conveyors

A telescopic conveyor is a loading and unloading device for trucks, wagons or ships and is generally installed in the immediate vicinity of the loading ramp and usually at the incoming or outgoing goods area of a distribution center.

The telescopic conveyor consists of a loading station, a conveyor belt, also known as a belt conveyor, and sections that can be moved into one another. If, for example, a truck drives up to the loading ramp, the device is extended (telescoped) into the trailer or container up to the unit load – or adjusted into the empty trailer to prepare for loading.

Flexible multifunctional telescopic conveyors

There is always a connection to the warehouse technology of the distribution center. Once the respective container has been loaded or emptied, the belt conveyor retracts into itself in a funnel shape. Depending on the infrastructure of the warehouse, there are also flexible multifunctional telescopic conveyors in addition to the permanently installed conveyors, which can be moved freely to the respective loading ramps at incoming and outgoing goods. A distinction is made between single and double telescopic conveyors. The latter can be extended with additional conveyor belts and axles as required and adapted to the existing conveyor landscape. The conveyor belts can be up to one meter wide and reach an extended length of eight meters and longer. Due to the short distances and the low manipulation effort (conversion), high handling rates are achieved at goods-in and goods-out.

Further information can be found under Outgoing goods – process steps and under Identification point (I-point).

Image source: TUP.com