Modularization of materials handling equipment with the SAIL standard

Current developments on the market present the following challenges:

- New component technologies require action

- Uncoordinated functional modeling leads to the formation of factions

- Large projects can only be managed with extreme engineering effort

- Heterogeneous individuality in the implementation of new technologies is a step backwards

- Standardization through function modelling is necessary

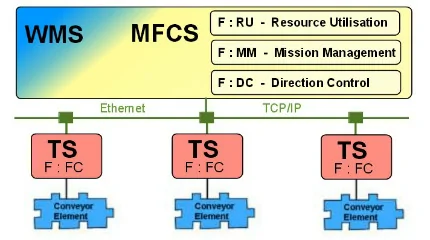

The solution lies in a standardized modularization of components based on a functional approach to the overall intralogistics system. To achieve this overarching standard, the first step is to clearly segment the conveyor technology functions. From this perspective, the logistical processes form the center of the considerations right from the start. The functional decomposition of an intralogistics system later enables system modeling with reusable modules, regardless of the technology used. This approach forms the basis for reducing complexity, as each system element can subsequently be assigned to a function. This forms the first stage of a hierarchy that creates clear rules for all processes in the plant. Examples of functions are resource utilization or transport order management (see also the methodology of VDI / VDMA SAIL.

In the next step, these defined functions are linked to corresponding system components. A component is, for example, a conveyor element in its smallest form. This creates the next stage for standardization and can now be carried out first for the individual components and then for their interfaces.

In the next step, these defined functions are linked to corresponding system components. A component is, for example, a conveyor element in its smallest form. This creates the next stage for standardization and can now be carried out first for the individual components and then for their interfaces.

The advantages

The advantages of this function-centered system modeling can be summarized as follows:

- Increased planning intelligence thanks to a modular building block view of the plant in the planning phase.

- Uniform and clear definitions of terms.

- Transparent functional evaluation in the procurement phase

“Customer says what he wants – supplier says what he delivers”. - Project partners agree on the same basis; this ensures a clear delineation of functions during interdisciplinary collaboration during the realization phase.

- A clear interface definition at the module boundaries during the realization phase.

- The manufacturer is not bound by any conventions within the functions.

- High availability through clear functional delimitation in the operating phase.

- Low-risk interchangeability of functionally defined subsections or components in the modernization phase.

Reusability of the encapsulated units

As a result, the new system architecture acts as a cost brake when modulating intralogistics material flow control systems.

Overall, the high degree of reusability of the encapsulated functions offers a clear cost advantage through reduced adaptation effort, greater standardization, a more mature degree of implementation and shorter commissioning times.

Further information on SAIL and the steps towards a standardized system architecture can be found here.