Innovation and Standardization is the title of a working group of the Intralogistics Forum of the German Engineering Federation (VDMA), in which well-known machine and plant manufacturers, IT companies, warehouse logistics companies, sorting specialists, and device and component manufacturers have come together. The working group has set itself the goal of creating added value for users and suppliers of intralogistics systems and system components by creating standards. The result of the work to date is the system architecture for intralogistics – SAIL.

Intralogistics projects are highly interdisciplinary and require a high degree of cooperation from all companies involved – from planners to suppliers to system operators. The success or failure of a project therefore depends not only on the quality of individual products or developments, but crucially on the systematic and sustainable interaction of all parties involved.

SAIL – the objective

SAIL is the result of the standardization efforts of the Intralogistics Forum within the VDMA. Its goal is to achieve effective collaboration between project partners from different trades by means of cross-provider architecture concepts. The core functions of an intralogistics system are systematized and standard control functions and interfaces (between the functions) are defined. Logistics systems based on SAIL are based on standardized functional components that enable easier integration of different systems through their cross-provider harmonization. The respective system provider is left to distribute the functions to different control levels, since SAIL is platform-neutral.

Editor’s note

SAIL is never considered in its entirety within the project planning; rather, the written ideas serve as a source of inspiration for the new digital and, above all, automated approaches that we are familiar with today. The most recent edition dates from 2016 (VDI/VDMA 5100 Sheet 1:2016-05).

SAIL – the components of a materials handling system

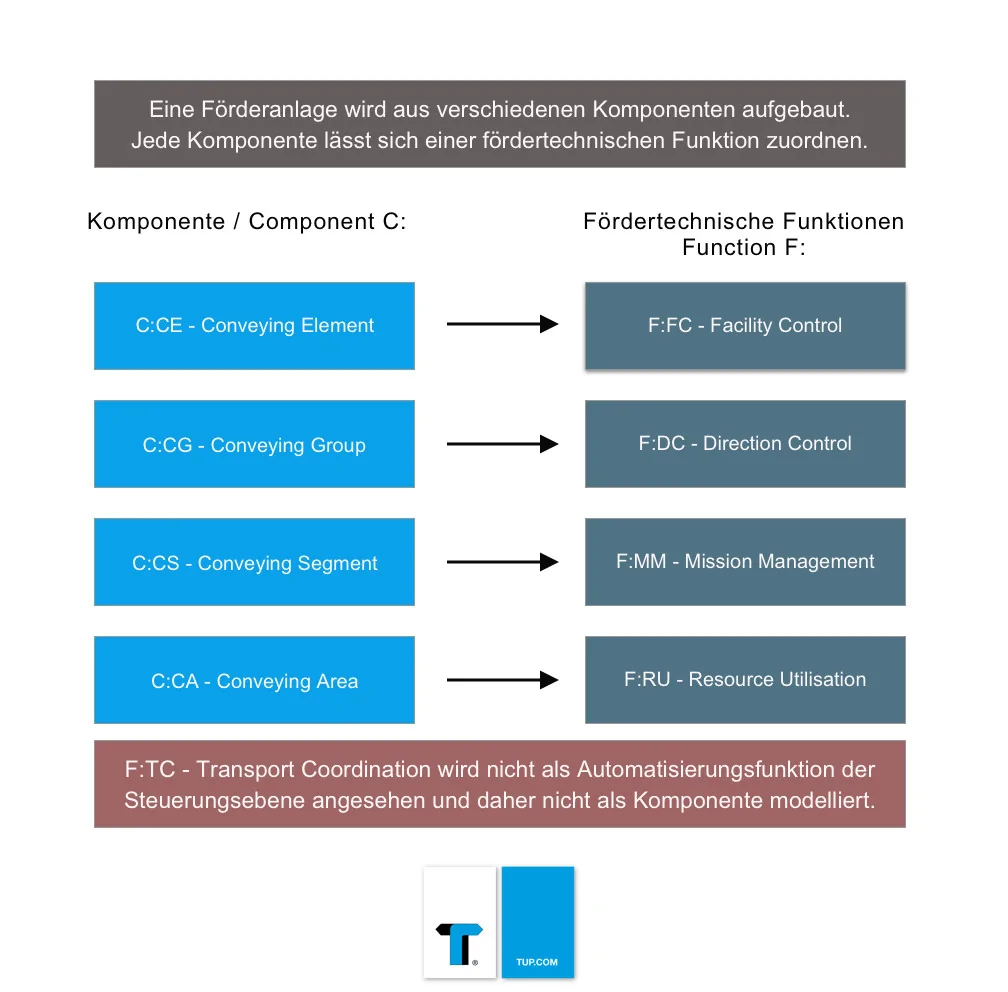

A materials handling system according to SAIL is built from a variety of components. Each component (C) can be assigned a materials handling technology function. The components serve to encapsulate the functions during modeling.

Conveying Element C:CE (conveying element)

A ‘Conveying Element’ is the smallest unit. It consists of a drive for the main conveying direction, the drives for the branching conveying directions and the associated sensors. It has only the function Facility Control F:FC (system control).

Conveying Group C:CG (conveying group)

A conveying group is characterized by the fact that it operates a group of conveying elements with the function Facility Control F:FC (facility control). It is therefore a collection of conveying elements that together can represent a complex system that outwardly represents a so-called branching point. Accordingly, the conveying group has a direction decision instance Direction Control F:DC (direction decision) with the corresponding operating parameters.

Conveying Segment C:CS (conveying segment)

A conveying segment is characterized by the fact that it provides the function Mission Management F:MM for a group of conveying groups.

Conveying Area C:CA (conveying area)

A conveying area consists of a group of conveying segments for which it provides the coordinating function of the resource utilization F:RU (resource utilization).

SAIL – innovation via standardized functions

Breaking down an intralogistics system by function enables platform-independent modeling with reusable modules. In contrast to the earlier practice of breaking down systems into different levels, the focus of the modeling is on the actual logistics and not the process. A reduction in complexity and a hierarchization inevitably arise as a secondary effect. Inspired by object-oriented programming, which has already led to a paradigm shift in other areas, SAIL transfers this approach to the modeling of intralogistics systems.

The following steps are crucial for the conceptual work of the plant manufacturers

- Primary plant disassembly according to functions and not according to levels

- Encapsulation of the found functions in components

- Standardization of the interfaces of individual components

- Provision of standardized control components analogous to available mechanical components

This results in the following functions (as already listed above)

- Direction Control F:DC (directional decision)

- Facility Control F:FC (facility control)

- Mission Management F:MM (transport order management)

- Resource Utilization F:RU (resource utilization)

- Transport Coordination F:TC (transport coordination)

SAIL – the function: Direction Control F:DC (direction decision)

The direction control function F:DC decides whether and in which direction a transport object should be conveyed at a decision point. This is done on the basis of defined operating parameters and, if available, the transport order data for the transport object that is currently at this point.

For identifiable transport objects, the transport order must be considered for each directional decision. Depending on the size of the facility, the structure of the transport orders and the available storage options, determining the direction of travel from the transport order is more or less complex. To ensure a fast response time at all times, the data is determined by the Mission Management F:MM function (transport order management).

For unidentified transport objects, there must at least be confirmation that it is an unknown conveyor object (UFO). If this is the case, it is usually possible to decide where this UFO is to be transported to. If UFOs are to be handled situationally and thus according to non-trivial strategies, a corresponding destination request must be made to an external instance of Resource Utilization F:RU (resource utilization). If the object is identifiable but has not been assigned a transport order (fare dodger), the treatment is based on pre-programmed rules or a parameterizable direction instruction. The same applies if the transport order management for a transport object has a transport order but this does not provide a specific direction instruction.

SAIL – the function: Facility Control F:FC (facility control)

The facility control function F:FC (facility control) directly operates the facility. It implements all decisions necessary for the intrinsic safety of the facility and the execution of a transport step. At this level, the decision is made as to whether or not transportation is possible. Generally, only the release of the downstream conveyor is considered for this purpose. The direction in which the material is to be conveyed is provided to the system control as the result of the function Direction Control F:DC.

SAIL – the function: Mission Management F:MM (transport order management)

The Mission Management F:MM function provides the relevant data for the Direction Control F:DC function (direction decision) (see also information in intralogistics) of the transport order. Its most important task is to provide information about the identification of the decision point and the transport object, whether a direction instruction exists and what its characteristics are. This process places high demands on the response time. In addition, this function group is responsible for creating, changing and deleting transport orders when requested by the Resource Utilization F:RU (Resource Utilization) function. The orders from F:RU do not place high demands on reaction speed.

When answering a direction query, the transport order is first determined via the ID number of the transport object. If this function is routable, the presence of the final destination of the transport is sufficient to determine the direction. Mission Management then determines the specific direction of transport itself. If this function is not routable, the transport order is searched to see if an instruction has been given for the current point. If so, this is transmitted; if not, this fact is transmitted instead. This provides the freedom to choose the appropriate implementation for very simple transport orders, with only the final destination specified, or with one or more value pairs of point/direction, depending on requirements.

SAIL – the function: Resource Utilization F:RU (Resource Utilization)

The Resource Utilization F:RU function knows the current occupancy status of the transport systems, their possible transport capacities and structure, the existing transport orders and the strategy parameters required to use the free resources. It decides which of several competing transport objects may use a free resource. This results in the assignment of a new transport order to the Mission Management F:MM function (transport order management) or the modification/deletion of an existing transport order. The Resource Utilization F:RU function group also uses the parameterization of the decision points in the Direction Control F:DC function group (direction decision) to pursue its operating strategies.

SAIL – the function: Transport Coordination F:TC

The Transport Coordination F:TC function group is the interface to the surrounding systems that do not belong to the material flow control system. These systems instruct the Transport Coordination F:TC function group to carry out their transports and receive all relevant data and status information from it. The Transport Coordination F:TC function is responsible for ensuring that all the transports it has been commissioned for are completed at the right time and in the right place. Even with a large number of transport orders (high-load operation), the appropriate operating strategies must be determined. For example, functions for grouping and sequencing multiple transport orders are also located here. To achieve maximum utilization, the availabilities of all areas and systems are considered and taken into account in the load control for individual transport systems. The organization of collective transports, tours and batch formations also takes place in the function group Transport Coordination F:TC.

SAIL – the advantages

All in all, the high degree of reuse of encapsulated functions in SAIL offers a clear cost advantage through reduced customization, higher standardization, a more mature level of implementation and shorter implementation times.

Advantages for the operator

- Transparency of all functions down to the last encoder

- No project risk involved in adapting the interfaces

- Harmonization of the architecture

- Shorter project durations

- Reliable operation

- Simplified servicing

- Increased system availability thanks to clear functional demarcation in the operating phase

- Flexibility for subsequent plant modifications

- Low-risk interchangeability of functionally distinct subsystems or components in the modernization phase (retrofit)

Advantages for the project manager

- Increased planning intelligence through unified and unambiguous definition of terms and communication methods

- Simple implementation of the customer’s wishes

- The customer says what he wants, the supplier says what he delivers

- Project partners agree on the same basis

- Harmonization of architecture as a cost brake

- Implicit benefits through reusable, standardized components

- Lower project costs with high solution quality

- Modular view of the facility in the planning phase

- Transparent function evaluation in the procurement phase

- Clear function demarcation in interdisciplinary cooperation during the realization phase

- Clear interface definition at the module boundaries during the realization phase

Summary SAIL

SAIL (System Architecture for Intralogistics) is a solution developed in the VDMA Intralogistics Forum to create standards for intralogistics systems and system components; this creates added value for both their users and their suppliers. Standardization ensures that all systems can work together systematically and sustainably. This brings many advantages, especially for intralogistics projects, which are highly interdisciplinary. SAIL is particularly innovative in that an intralogistics system is not divided into individual system levels; instead, it is broken down by function.

For more information on this topic, see also Functions of the warehouse and Storage zone.