Pareto efficiency in intralogistics

The Pareto efficiency (also Pareto optimum) orientation method describes a theoretical state from which the optimization of a sub-construct (e.g. part of a system) inevitably causes the opposite development of another sub-component. In intralogistics, Pareto efficiency is used, for example, in the optimization of the material flow calculator (MFR).

The optimum is named after the Italian economist and sociologist Vilfredo Pareto, who also coined other terms such as the Pareto principle with his work in welfare economics, which also demonstrates effective behaviour in the area of optimization.

The number of all Pareto optima is bundled in the Pareto set. If, in a specific case, it is weighed up whether the optimization of a parameter improves the state without worsening the performance of other influencing factors, this is referred to as a Pareto criterion.

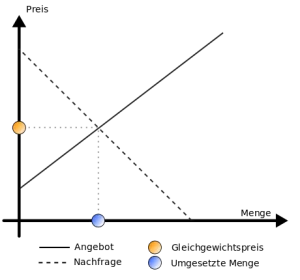

An example: If the demand for  Labor demand and labor supply meet each other’s ideal requirements, Pareto efficiency is achieved. As any development involving the human factor is dynamic, the optimum functions as the ideal state for optimizing a wide variety of movement mechanisms, such as on the labour market (see diagram) or the MFR in intralogistics.

Labor demand and labor supply meet each other’s ideal requirements, Pareto efficiency is achieved. As any development involving the human factor is dynamic, the optimum functions as the ideal state for optimizing a wide variety of movement mechanisms, such as on the labour market (see diagram) or the MFR in intralogistics.

An example from intralogistics: Increasing the throughput of goods in a conveyor system results in a backlog of goods. Without investing in a buffer zone in which the goods are temporarily stored when the system is at maximum capacity, the MFR runs the risk of being prone to errors.

In the case of continuous optimization in intralogistics (e.g. at the level of the MFR or the entire value chain in supply chain management), one usually operates with a large number of Pareto optima that affect the process and must be weighed against each other for a decision in a mathematical comparison. Secondary parameters also play a role in the optimization within a system (e.g. MFR), which do not directly result in the Pareto optimum, but which, as operational variables, have a momentary influence on the way to the Pareto optimum.

Pareto efficiency as an infinite loop

In the real scenario, Pareto efficiency is a utopia because the conditions under which the MFR operates never remain rigid: Due to continuously changing external factors (such as fluctuating order volumes, modernization of external mechanisms, reorganization of internal processes), new gaps inevitably always arise, which can be closed by optimizing the respective area.

Consequently, only partial Pareto optima can be achieved within an overall system consisting of individual components such as the MFR. The maximum tension within a state optimization decreases over time because influencing factors require continuous optimization.

If the arc is overstretched and the optimization of one parameter causes the deterioration of another, this is referred to as a trade-off. The MFR in the dynamic state shows a constant need for optimization, the pursuit of Pareto efficiency is not a real goal, but rather a theoretical tool and therefore a vision.

Information on targets and optimization within the material flow calculator can be found under Modern material flow control.

Image license: © Graphic Supply and demand in a market economy(CC BY-SA 3.0)/ Teaser image: WerbeFabrik (CC0)