Material flow simulation

Material flow simulation has a wide range of applications in warehouse logistics. It is ideally used as a tool for optimising and forecasting key figures in all phases of the life cycle of a logistics system, in sales and marketing, in planning and implementation phases as well as in ongoing operations. The fields of application range from the simulation of a sub-area of production or the warehouse with its warehouse key figures to the complete supply network.

The Association of German Engineers (VDI) defines simulation as “the simulation of a dynamic process in a system with the help of an experimental model in order to gain knowledge that can be transferred to reality” [VDI Guideline 3633 (2010)].

This means that a piece of reality is reproduced in the computer and experiments are carried out in order to be able to make statements about the behaviour of the real system.

Simulation methods are used in a wide variety of areas, from weather forecasting to flight simulation. The so-called process or material flow simulation is used to visualise company processes. This form of simulation is also known as discrete event-orientated simulation. In principle, it involves modelling the flow of unit loads through a process with defined times and thus simulating flows of people, business processes or traffic flows, for example.

Material flow simulation in sales and marketing

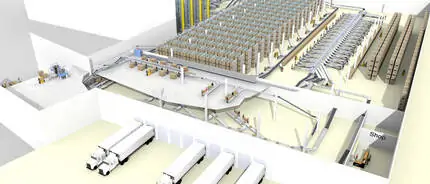

Plant manufacturers, machine builders or warehouse suppliers use simulation in the sales phase of production and logistics systems to quickly and realistically communicate possible solutions to the end customer and thus gain their trust.

This does not involve creating a detailed simulation model of the system that can already determine throughput rates, capacity utilisation values or throughput times . Instead, an easy-to-create, high-quality animated visualisation is used to develop a common understanding of the planned process.

Material flow simulation in planning

With the help of material flow simulation, new systems can be checked for throughput, sufficient dimensions, throughput times, performance limits, disruptive influences, labour requirements and other parameters before construction begins. Simulation also makes it possible to evaluate and compare different planning variants. This often helps with fundamental decisions at the start of planning.

A simulation model that grows with the level of detail and knowledge of the planning accelerates the planning process and supports an iterative approach to finding solutions.

To optimise existing systems, they are mapped in their current state and specific modifications are made within the model. For example, the use of a different control strategy can lead to a higher throughput. Carrying out these analyses on the real system would take a lot of time and incur high costs. In contrast, changes to the system can be made easily during the planning phase using the simulation model without affecting ongoing operations.

Material flow simulation in realisation

A simulation model with the most realistic possible representation of the IT structure of a system serves as a template for creating the system control when programming the control system. The classic control levels are, on the one hand, PLC controls, but also material flow computers, warehouse management and ERP systems.

The model can also be used for the virtual commissioning of real control systems, as it can be coupled with the real system at various control levels if set up accordingly. The control logic in the simulation model is replaced by the external control system. A coupling of model and real control system is also referred to as emulation.

Emulation makes it possible to put the system control into operation even before the real system has been completed. In addition, the control system can be tested in a wide variety of scenarios at the touch of a button, e.g. under high system load or in critical situations. Furthermore, error situations in the emulation model can be reproduced at will, as the model always behaves the same under unchanged conditions.

Further information can be found in the article“Supply chain simulation”

Image source: © TGW Logistics Group GmbH