Lot size

The batch size defines the number of parts within a series that pass through production in one batch without interruption. If orders are combined in a production batch, series or batch, there are economic reasons for this, which are based on lower set-up costs and shorter travel times for the production parts.

Definition of terms and size interval

The general term for this bundling of parts is batch formation. When it comes to their specific dimensions, the term batch size is used in manufacturing. In intralogistics, the terms batch size or series size are also used.

The limit of the batch size is linked to the maximum utilization of the transport elements and the capacities of the stations approached. The handling of the parts must not fall victim to a process bottleneck.

Planning the batch size in advance

Compared to individual or mass production, the challenge in determining the batch size lies in determining a production quantity in advance. The receipt of a customer order can, for example, be used by the supplier in the form of a notification to combine similar orders in a batch or lot in order to optimize the supply chain.

If production is not linked to an order, two opposing items overlap when determining the batch size: The cost of setting up the equipment, which is incurred per batch, must be weighed against the storage costs incurred in the event of overproduction.

Calculation using Andler’s lot size formula

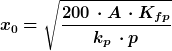

The consideration of the opposing factors of set-up costs and storage costs leads to the goal of the optimal batch size 1, which has the goal of optimizing the value chain. Accordingly, this is a batch size calculated in advance (unique number of production parts in a batch), which includes consideration of the economic factors. To achieve this, the industry uses Andler’s batch size formula:

(where A = annual sales,Kfp = lot size fixed costs, kp = variable unit costs, p = interest and inventory cost rate)

Introduced to the German-speaking world in 1929 by Kurt Andler, this framework was used to determine batch sizes in single-stage industrial production. As a result of increasingly complex internal processes, Andler’s formula has now multiplied in modified form and is usually linked to the individual operational processes of a company.

You can find a good example of the calculation of batch size 1 according to Andler’s batch size formula in the PDF of the Commercial Vocational School 4 in Nuremberg.

Batch size in practice:

In the course of the need for the most efficient supply chain possible and the communication of its components under the umbrella brand “Industry 4.0“, the batch size is one of the key factors for achieving economic goals and ensuring the conservation of resources. This is because the creation of unnecessary set-up costs results in a lack of economic efficiency, which can lead to disadvantages in international competition.

You can read about the principles according to which production can be carried out under Production principles.

Teaser image: ©TGWmechanics / License:(CC BY 3.0)