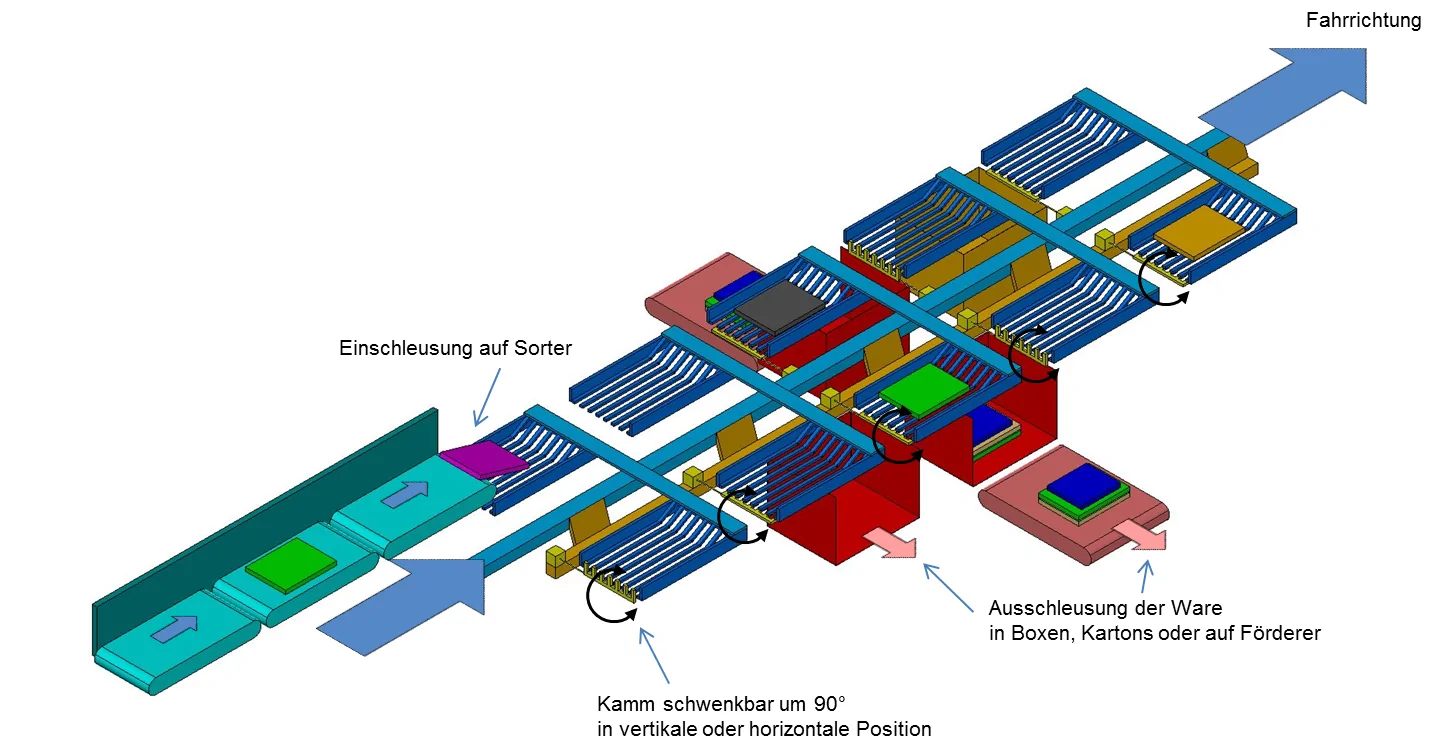

Comb sorter

The comb sorter sorts order-related goods from a continuous flow system into containers provided for this purpose. In conveyor technology, it is one of various sorting systems such as the circular sorter, the pocket sorter or the tilt-tray sorter.

In the comb sorter, the material to be sorted is placed on fork-shaped trays, the bottoms of which are provided with longitudinal gaps. The containers into which the goods are to be sorted are located underneath the trays. Sorting often takes place directly in shipping cartons. There is a comb in the area of each shipping carton. If a conveyed item is to be discharged, the comb is positioned on the corresponding shipping carton. The combs are attached to torsion bars which move the teeth from horizontal to vertical. The teeth of the comb then reach through the forks of the container, strip off the sorted goods and they fall directly into the box below. As the sorted goods “hit” the teeth of the comb at full speed, they should not weigh more than 100 kilograms, otherwise either the goods or the comb could be damaged.

Areas of application for the comb sorter

The comb sorter is mainly used for sorting books, CDs, DVDs and folded textiles, as these are easy to stack. With the comb sorter, the goods are stacked directly from the sorter into the shipping cartons, eliminating the need for additional manual packing. There is only a short distance between the fork-shaped tray that transports the goods and the container into which they are discharged. This enables the goods to be precisely stripped and collected.

The advantage of a comb sorter is the gentle discharge directly into shipping cartons. When a carton has reached the filling level, the carton is replaced manually or fully automatically, depending on the system. The maximum load of a comb sorter is approximately 14,000 sorting units per hour.

Further information on sorters can be found under linear sorters.

Teaser image: © 7artman – Fotolia.com

Graphic: © TUP.com