The order picking time in intralogistics

The picking itself and the associated picking time are usually a conglomeration of personnel- and cost-intensive processes that are company-specific, and their complexity depends on the company’s business processes. The picking time is the time required to complete a picking order. The picking time usually starts when the picking order is handed over to the picker and ends when it is handed over to the order collection point or to a materials handling system.

The picking time consists of the base time, pick time and travel time (transport and warehouse logistics, 8th edition, page 399); in addition, there are the so-called dead time and the distribution time, both of which are distributed over the base and gripping times. The base time takes up an average of 27 percent, the pick time 25 percent and the travel time 48 percent per order. The final report on the IGF project 18139N Pick-by-Local-Light / FML has yielded similar results.

Picking times equal picking performance

The time required for picking is one part of the picking performance. The picking performance is defined by the number of picked orders per unit of time, which in turn is expressed in picks per hour, bins per hour or items per hour.

Picking Time Formula

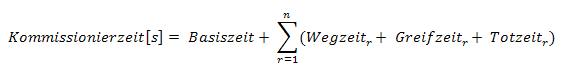

Apart from the base time, all components of the picking time depend on the number of items in a picking order. Therefore, the following (german) formula is used to calculate the picking time, where n represents the number of items in the picking order:

Important: Picking is defined in the german VDI guideline 3590 (VDI94).

Summary

The picking time shares are of different sizes for the different picking types (pick-by-scan, pick-by-light, pick-by-vision or pick-by-robot). If different picking types are used, they are added together. This results in the picking performance, which is measured in picks per hour. The order structure, the picking system used, the capacity of the staging units and shipping units, and the range of products are factors that influence picking performance and time. It should be noted that The shorter the picking time, the cheaper the respective product or material for production can be offered on the market (Warehouse Management – 4th, newly revised edition, page 40).