Logistics key figures and key figure systems

Table of contents for easier navigation of the article:

- Key figures

- Functions of key figures

- Classification of key figures and key figure systems

- Traditional key figure systems

- Traditional key figure systems – The DuPont System of Financial Control

- Traditional key figure systems – The ZVEI system

- Traditional ratio systems – The profitability and liquidity ratio system</

- Traditional ratio systems – The Ratios au Tableau de Bord

- Traditional performance measurement systems – The Managerial Control Concept

- Modern performance measurement systems

- Balanced Scorecard (BSC)

- Supply Chain Operations Reference Model (SCOR)

- Key performance indicators in logistics

- Key performance indicator system in intralogistics and distribution centers

- Summary

The tasks of a company must be planned, monitored and controlled. A key performance indicator system is helpful for this purpose. In such a system, all the key figures within the company are brought together. This makes it possible to assess and evaluate the performance of a company and its individual divisions and departments.

Key figures

Transparency of processes and interacting factors are necessary to manage a company, especially in the field of logistics. For many of these factors, it is possible to measure them with the help of key figures. Data that can be used to depict a small section of operational facts, structures and processes which represent the state of a company in a consolidated form can be defined as key figures.

One advantage of using key figures is the reduction in complexity and the associated guarantee of a quick overview. In this way, the following activities can be simplified:

- Analysis

- Ongoing planning

- Management

- Monitoring

Another advantage is the ability to measure the throughput time for individual processes and for the overall process, for example in the form of key warehouse figures. Stocks and the space used can be mapped on the basis of static capacity utilization and the utilization of technical resources.

Key figures are characterized by their informative nature, quantifiability and specific form.

Use of Key Figures

With the help of various analysis functions, key figures can be used in a comprehensive way. Possible applications include, for example:

- Suggestion function

- prioritization function

- Communication function

- control function

- monitoring function

- Operationalization function

The suggestion function draws attention to faults and irregularities. The basis for this is the continuous recording of operating data, which can be used to identify deviations and potential problems. A prioritization and default function is created by defining fixed default values. Control processes (communication/control function) can be simplified by using key figures. Data from workforce management can be used to assign employees to different tasks and locations. The monitoring function becomes clear when the target/actual status is compared on an ongoing basis. The last important function is the operationalization of objectives.

Structure of key figures and key figure systems

Sowohl Kennzahlen als auch Kennzahlensysteme werden in der Regel gegliedert und geordnet, um einen Überblick zu verschaffen, sprich, um schnell und einfach Einsicht sowie Übersicht bezüglich bestimmter Sachverhalte zu vermitteln.

Es gibt verschiedene Varianten, um Kennzahlen zu ordnen. Mögliche Gliederungen lauten:

- Mathematisch/statistisch

- Gliederung nach dem Zweck

- Gliederung nach dem zeitlichen Horizont

- Gliederung nach der Art

- Gliederung nach der Grundlage

On the mathematical or statistical side, there are both absolute and relative figures. The relative figures include classification, relationship and index numbers. While the measurements for absolute figures only take place in relation to a certain period of time, for relative figures the ratio of a part to the whole is given (classification numbers), the ratio of different sizes to each other (relationship numbers) and the temporal development (index numbers).

In the breakdown by purpose, there are descriptive key figures (analysis key figures), which reflect the actual situation, and normative key figures (control key figures), which are used to influence and control processes.

In the breakdown by time horizon, strategic, tactical and operational key figures are used. Strategic key figures are characterized by a high degree of success and a longer-term time frame. Operational key figures are used more for measuring efficiency. Tactical key figures establish the connection between the strategic and operational key figures.

When organized by type, there are structure/framework key figures, productivity/performance key figures, profitability key figures, and quality key figures.

When organized by basis, key figures related to performance, costs and work data play a role. With performance figures, quantities are assessed in relation to the time required. The throughput of a quantity should be assessed within a certain time unit. Cost figures, for example, are process costs, and work data figures are absolute numbers of quantities produced.

There are also various ways of structuring or organizing the key figure systems . On the one hand, key figure systems can be subdivided on the basis of six different systematization characteristics. On the other hand, there are not only pure characteristics. Instead, there are also corresponding mixed forms. The systematization characteristics are:

- Linking of elements (calculation systems and classification systems)

- Method of development (inductively derived systems and deductively derived systems)

- Type of facts to be measured (measurement of structures and measurement of processes)

- Temporal dimension (planning systems and control systems)

- Operational functions (intralogistics and warehouse management as well as production, finance)

- Use orientation (analysis system and control system)

Example:

The systematizing characteristic of the linking of elements forms the formal structure of a system of key figures. In the following, we will describe, using accounting systems as an example, how a system of key figures is designed using the characteristic of linking elements:

The structure of the system is tree-like, with a top key figure at the highest level. The most important statement in the calculation system is made by the top key figure. It is successively broken down into further key figures. The process is carried out over several levels until certain measured values are reached.

A major disadvantage is that auxiliary key figures are often needed to clearly show how the top key figure was created. Only by showing connections can the necessary operationality for analysis purposes be established.

In a calculation system, the aim is to use all key figures as input for the top key figure. Calculation systems are insufficient for the demands of reality, because a company cannot be controlled with just one key figure.

One way to overcome the limitations of these calculation systems is to use classification systems. In this case, the linking of key figures takes place via a logical structure. It is not necessary to include auxiliary key figures in the system. The structural design is implemented, for example, by grouping according to objects. However, it is also possible that connections are not clearly visible.

Traditional key figure systems

As already mentioned, a company’s key figures are combined in a corresponding key figure system. The aim of such key figure systems is to be able to provide specific information about a particular situation using absolute figures and/or ratios. There are both traditional and modern key figure systems. The traditional key figure systems include:

- The DuPont System of Financial Control

- The ZVEI system

- The profitability and liquidity key figure system

- The ratios au tableau de bord

- The managerial control concept

The most common system of key figures is the DuPont system of financial control. Many other systems of key figures are based on this fundamental system. The least frequently used system is the managerial control concept.

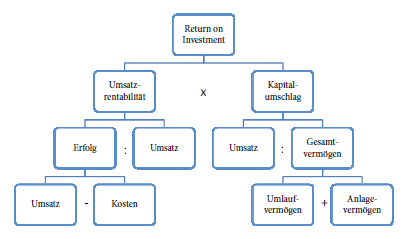

Traditional performance measurement systems – the DuPont system of financial control

One of the traditional performance measurement systems is the DuPont system of financial control. It is probably the most widely used system and can therefore be considered the mother of all performance measurement systems.

The DuPont system is also described as a calculation system that is used primarily for analysis. The primary goal is not to maximize profits, but to maximize return on investment.

The benefits of using the system are manifold. These include the following aspects:

- High informative value

- Clarity

- Descriptiveness

- Option for expansion

- Evaluation of operational performance

A disadvantage is that certain cost considerations are not available and a comparison with other key figures is necessary for assessment.

Traditional key figure systems – the ZVEI system

The ZVEI system was developed by the German Electrical and Electronic Manufacturers’ Association (Zentralverband der elektrotechnischen Industrie) and is more prevalent in Germany.

The ZVEI system is used as an instrument for analysis and control. This is possible through internal and inter-company comparisons. The system is industry-neutral and allows for growth and structural analyses. Another feature of the system is that it can be used as a planning tool. Furthermore, as with the DuPont system, the cause-and-effect relationships should be revealed by breaking down a key figure. Ratios and differentiation make this disclosure possible. The ZVEI system improves and refines the DuPont system.

Traditional key figure systems – the profitability and liquidity key figure system

Compared to the two key figure systems described above, the profitability and liquidity key figure system contains relatively few key figures. However, it does contain two key figures (profitability and liquidity). This variant, which is also referred to as the RL key figure system for short, is a pure classification system. The development of the profitability and liquidity ratio system was intended to create a multi-objective system instead of the previous single-objective pursuit.

The system consists of four parts: a general part and a special part, each with a success and a liquidity component view.

In order to control the company as a whole, the most important key figures from the following areas are linked:

- Cost accounting

- financial planning

The RL key figure system is used primarily as a tool for planning and control.

Traditional key figure systems – the ratios au tableau de bord

The concept of this system is that the ratios au tableau de bord can be used as an individual management tool. To this end, the system must be developed in a situation-specific way and tailored to individual business units.

Depending on what is needed, a dashboard can be created with several metrics. These include:

- financial metrics

- non-financial metrics

- historical metrics

- future-oriented metrics.

Up-to-date information is needed to create the metrics. Because data from accounting is only considered supplementary, it is quite possible that several dashboards exist due to a lack of coordination.

Missing or poorly revised data can cause the metrics to become confusing or outdated over time. Local data collection can lead to the overrepresentation of an area.

The advantages are flexibility and rapid adaptation to new circumstances.

As the name suggests, the system is mainly used in France. Outside of these national borders, the variant has not been widely adopted. According to scientists, the reason for this is the lack of international reports and descriptions. Initial findings were only published after several years of application and experience. The Balanced Scorecard (see below), whose cockpit is basically similar to that of the Ratio au Tableau de Bord, has been much more successful.

Traditional Key Figure Systems – The Managerial Control Concept

This concept was created as a decision-making and control system. With the Managerial Control Concept, company management has several key figures at its disposal, in contrast to previous key figure systems, where only one or two were reported.

The Managerial Control Concept is divided into the following classic functional areas:

- Production

- Finance

- Sales

In addition, the managerial control concept includes the following hierarchies:

- top management

- middle management

- lower management

Information is passed on and summarized from one hierarchical level to the next higher level. This division creates a clear and concise way of conveying information.

Modern performance measurement systems

In the context of key figures and key figure systems, further systems have been developed that serve to assess and evaluate a company’s performance. These new performance measurement concepts are used to break down, expand or derive the rigid, formal structures of traditional models. Such performance measurement systems include the Balanced Scorecard (BSC) and the Supply-Chain-Operations-Reference-Model (SCOR). The main focus of both concepts is on operational execution.

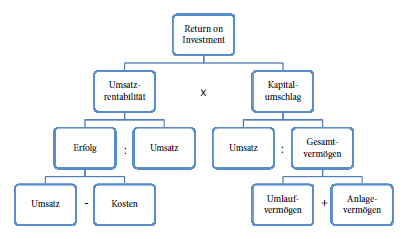

Balanced Scorecard (BSC)

The Balanced Scorecard concept can be seen as a communication, learning and control concept for implementing a strategy. This is intended to avoid the weaknesses of performance measurement systems that are based purely on financial metrics. The Balanced Scorecard is a holistic concept that considers four different perspectives:

- Supplier and customer perspective

- Innovation and knowledge perspective

- Financial perspective

- Internal process-oriented perspective

The supplier and customer perspectives use data on customer satisfaction, market share and service levels. The innovation and knowledge perspectives take into account employee know-how, employee satisfaction and innovations. The financial perspective considers cash flow, company value and return on capital, while customer service and operational processes are important for internal business processes.

The advantages of the Balanced Scorecard are:

- Orientation towards future-oriented key figures

- Consideration of cause-and-effect relationships

- Possibilities for individual adjustments

One disadvantage is that the Balanced Scorecard does not provide a methodology for developing specific key figures. No procedure can be found in the literature that describes how to select or calculate key figures. Furthermore, the Balanced Scorecard focuses exclusively on top management. It is created from the top down.

Supply-Chain-Operations-Reference-Modell (SCOR)

The SCOR model looks at several aspects of cross-company processes. The focus is on the entire supply chain, even if the model is always based on the perspective of an individual company.

The characteristics of the model are industry neutrality and the description, standardization, measurement and evaluation of process chains. The model consists of four different levels, which are organized hierarchically. It is also differentiated according to internal and external performance characteristics.

The tasks performed at each level are as follows:

Ebene 1: Top-Level

- Process category “Planning” is monitored

- “Procure” process category is monitored

- “Manufacture” process category is monitored

- “Deliver” process category is monitored

Level 2: Configuration level

- Defining different modules

- Decomposition of the supply chain into sub-processes

Level 3: Process element level

- Breakdown of the modules into individual elements

- Assembling the elements into a causal chain through input-output relations

Level 4: Implementation level

- Detailing the process elements

- Breakdown of the elements into different activities

The advantage of the model is that companies can analyze their current processes in depth. The hierarchy, the coordinated structure and the standardized framework enable this detailed analysis. This creates a uniform standard for performance measurement and communication across the entire supply chain. In addition, companies can learn from partners and their best-practice approaches.

The disadvantage of the model is that the cross-industry application results in a high degree of abstraction. It is possible that the dependency of partners will increase, resulting in companies losing sovereignty.

Although the SCOR model has not really been able to establish itself to date, it can be seen as a suggestion. The level model makes it relatively easy to transfer to other areas of application.

Key performance indicators in logistics

Categorization of key performance indicators: finances, customers, processes

Three groups of key performance indicators can be distinguished in logistics. Productivity indicators, profitability indicators and quality indicators. Productivity indicators measure productivity at a technical and personnel level, profitability indicators measure logistics costs and company-specific results, and quality indicators measure the degree to which targets have been achieved.

Dr. Hans-Ulrich Krause and Professor Dr. Dayanand Arora have summarized the most important KPIs in their handbook Controlling-Kennzahlen as follows:

- Key financial figures:: Earnings KPIs, profitability KPIs, liquidity KPIs, cash flow KPIs

- Key figures for customers: Customer relationship metrics, marketing communication metrics, price management metrics

- Process key figures:: Project metrics, quality metrics, supply chain management metrics

Logistics naturally plays a key role in supply chain management in particular. Its key performance indicators are divided into the following four sub-items: Procurement efficiency, incorrect delivery rate, incorrect delivery rate and delivery readiness level. Key performance indicators are difficult to combine and compare due to their underlying complex processes. They are therefore usually viewed or assessed from different perspectives. For example, the cost center tends to look at the profitability and cost coverage of a company, while those responsible for logistics tend to look at throughput or the number and length of round trips.

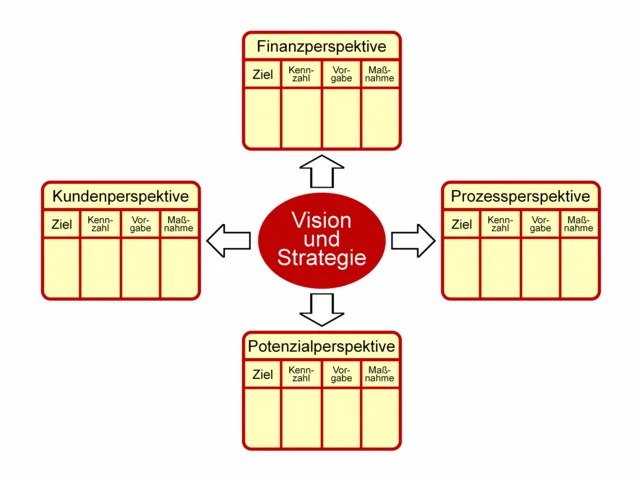

Key figure system in intralogistics and distribution centers

A complete bundling of all key performance indicators in warehouse and distribution systems is possible today, but difficult due to the multi-layered nature of complex systems. Using a predefined key performance indicator system, on the other hand, it is possible to compare different key performance indicators with each other in a meaningful way and to generate a so-called ordered totality of key performance indicators. The aim of such a system is to provide clear information on the individual processes and the associated objectives.

A key performance indicator system is used in the management and controlling of logistics systems. The figures calculated in it, usually from raw data, provide the employee with a significant process overview. A distinction is made between verifiable characteristics (performance) and a comparable evaluation (benchmarking).

As already described, a KPI system fulfills various functions. These include the information and analysis function, the control function and the documentation function. So how could an integrated KPI system for internal logistics in a distribution center be structured? Dipl.-Ing. K. Heptner investigated this question and developed the following graphic, which is based on three superordinate key figures. The first two points belong together.

- Delivery costs: Total costs of the distribution center divided by the number of delivery items per time unit

- Shipping value factor: Quotient of total costs and sales value of goods per time unit

- Lead time fulfillment rate: Quotient of target and actual order lead time

- Delivery quality: Function (mapping) of delivery readiness level and factor as well as incorrect delivery rate and factor (see also Perfect Order Fulfillment)

Einen ähnlichen Ansatz verfolgt die VDI Guideline 4400 Sheet 3. Sie setzt folgende Darstellung beziehungsweise Ziele eines Kennzahlensystems voraus:

The VDI Guideline 4400 (Sheet 3) takes a similar approach and assumes the following presentation or objectives of a KPI system:

- High logistics efficiency (overall picture)

- High logistics performance (short throughput times, high productivity, high level of deliveries)

- Low logistics costs (low Inventory costs, low process costs)

Operationalization of the logistics goals

The KPIs themselves serve to operationalize the logistics goals.

Important here:: In addition to the performance indicators for measuring logistics performance and the cost indicators for measuring logistics costs, the KPI system contains so-called structural indicators. They are not assigned to any of the objectives in the context of benchmarking studies.

Examples of structural indicators:

- Picking order items per operating calendar day

- Goods delivery per operating calendar day

- Transport time to customer per consignment

- Transport distance per consignment

- Shipping weight per consignment

In addition to the KPI systems already described here, there are also special KPI systems in intralogistics that are individually tailored to the individual processes.

Summary

The tasks of a company are planned, monitored and controlled with the help of a key performance indicator system. In such a system, all key figures available in the company are brought together, which in turn can fulfill different functions. There are both traditional and modern KPI systems, which are used to varying degrees and also differ in terms of their strengths and weaknesses. What they all have in common is the aim of presenting complex facts and assessments of the company’s performance in a simplified, easy-to-understand form.

Further links:

General information on operating data and its collection can be found under Operating data collection.

Further information on key figures, the value creation process and logistics controlling can also be found under Supply Chain Management (SCM); the corresponding optimization using process sequence management is also interesting.