Bulk detection in extra- and intralogistics

Bulk detection is used to detect several data carriers or identification marks, so-called tags, in a matter of seconds using RFID technology. Even if this type of capture does not yet apply to every process in extra- and intralogistics. In practice, it has one decisive advantage over other AutoID methods, such as barcode scanning: it saves time.

In future, logisticians will be able to record hundreds of products simultaneously using RFID technology and the“Electronic Product Code“, which is attached to the transponder and stores the information. Bulk recording optimizes processes within production and logistics chains and is primarily used for incoming goods, outgoing goods and stocktaking.

This type of recording is already common practice in the fashion industry in particular. This is also because textiles are currently the best environment for this technology. RFID still suffers from technical collisions, such as the effects of metal and liquids. These include surface reflection, absorption by water-containing materials and classic steel construction. They seriously disturb the electromagnetic field. This is a decisive reason why bulk detection is not used everywhere due to the lack of robustness of the transmission path, also known as the air interface.

Different detection methods and materials for RFID transponders

Manufacturers and logistics companies are responding to these collision possibilities and are already using different materials, frequencies and detection methods. In some processes, the RFID transponders are not captured at exactly the same time, but very quickly one after the other, so that there is no collision interference with regard to the amount of data. The data packets are then compared one after the other by the ERP system. In addition, particularly robust RFID materials have already become established in some cases, where the transponder is exposed to environmental conditions of minus 30 degrees Celsius and up to plus 60 degrees Celsius. Even extreme humidity, poor weather conditions and repeated washing have not affected the material and the resulting capture quality. A similar patent is described under“Bulk detection of returnable drinks kegs with transponders“.

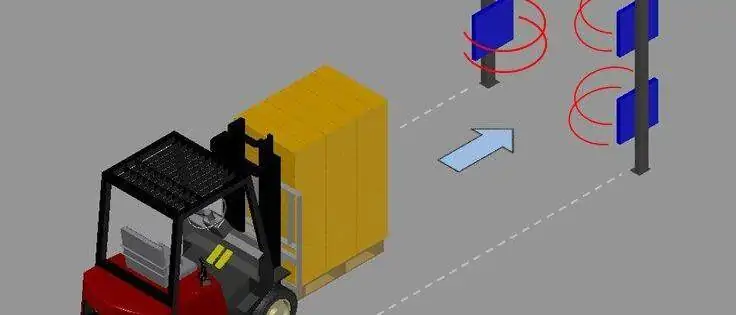

Bulk detection in extralogistics

UHF tunnel gates are currently gaining ground in extralogistics. Here, the truck and its load travel through a type of tunnel in which a homogeneous field strength distribution prevails. This enables the complete detection of large quantities of passive transponders in the entire reading range. This is completely shielded from the outside world in order to avoid the aforementioned collisions.

Basically, the following parameters are the focus of a functioning bulk detection system:

- System frequency

- Data volume

- Type and number of transponders in the reading field

- Alignment and position of the transponders in relation to each other

- Alignment and position of the transponders in the antenna field

Further information on coding technology and its structure can be found under EAN, GTIN and GS1 standard.

Image source: © TUP