Out-of-stock traditionally refers to a shelf space in a brick-and-mortar retail store that no longer contains the intended item.

The distinction between out-of-stock and the term shortage is that out-of-stock (OOS) refers exclusively to the direct relationship between the retailer and the end consumer, so the latter is the one who encounters the out-of-stock situation. While the original definition of OOS describes the situation in which a shelf label declares the product but the corresponding shelf space is empty, more modern definitions are broader: on the one hand, OOS now refers not only to brick-and-mortar retail but also to e-commerce (online retailing), but on the other hand, it also focuses more on the consumer’s point of view.

Definition of Out-of-Stock: A product not found in the desired form, flavor, or size, not found in saleable condition, or not shelved in the expected location – from the perspective of the consumer.

Roland Berger Strategy Consultants (2003),“Optimal Shelf Availability: Increasing Shopper Satisfaction at the Moment of Truth,” ECR Europe.

Measuring out-of-stock

Out-of-stocks can be measured using a variety of methods:

- Manual measurement

- Using POS (point of sale) data

In the very labor-intensive manual measurement, the shelves are systematically checked on site for gaps. In contrast, OOS are predicted by mathematical-statistical methods based on sales patterns, using specific data from the point of sale. For example, an item’s sales patterns can be derived from turnover frequency and volatility (fluctuations at specific time intervals/time series).

If an out-of-stock situation is (statistically) identified in this way, the decision-maker is informed and the staff on site check whether or not there is an OOS. Within the mathematical-statistical measurement methods, two methods can be distinguished: level analysis and frequency analysis.

In the case of the level analysis, an OOS can be determined with a high degree of probability by setting lower limits for the daily sales of an item; if these limits are exceeded, there is a high probability of an out-of-stock situation.

- The frequency analysis, on the other hand, focuses on a fixed time interval that determines the time between sales of a particular item; if this interval exceeds the limit (the time interval increases), this is also most likely due to an out-of-stock situation.

Important: To implement mathematical-statistical methods, it is important to have a good database, especially with regard to historical data, aggregation levels and quality. However, such methods can only be used to approximately predict items with a relatively high constant turnover rate and low volatility.

The out-of-stock rate

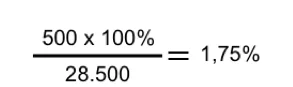

The out-of-stock rate expresses as a percentage how high the proportion of unavailable items is in relation to the total number of items stocked (or requested). To clarify, here is a clear example from e-commerce: a web shop operator cannot deliver 500 of 28,500 ordered items within the promised two working days of the order.

The out-of-stock rate

This means that the out-of-stock rate is 1.75 percent.

In addition to simply calculating the OOS rate, it makes sense to segment OOS situations according to when they occur, for example by day, time of day, promotional periods, and by manufacturer and product group.

Jon Meyer, Universität Bremen

This key figure (key ratio) indicates the quality of logistics/merchandise management and sales planning. It also provides insights into sales losses due to unmet demand. In general, out-of-stock situations are to be viewed negatively from a business perspective, as they reduce sales, complicate sales planning and cause unnecessarily high logistics costs (see also inventory costs).

Causes of OOS

The most common causes of unplanned out-of-stocks include:

- ordering problems

- inadequacies in shelf replenishment

- delivery and placement problems

- listing differences

Overall, it can be said that in almost three-quarters of all cases, the causes of OOS lie in the practices and processes of the stores. Only in 28 percent of cases can the supply chain be identified as the source of the cause. […] The results of our study suggest that future improvement measures should also focus on the last 50 meters of the supply chain.

Customer reactions to OOS

There are several ways in which customers can react to an out-of-stock situation:

- Abandoning the purchase (lost sales for manufacturer and retailer)

- Postponing the purchase

- Changing the store (lost sales at the expense of the retailer)

- brand change (lost sales at the expense of the manufacturer)

- variant change

Thus, OOS can lead to lost sales for both retailers and manufacturers, as well as to buyer migration, in that the desired item is not purchased, purchased elsewhere or substituted with a product from a different manufacturer. There are numerous measures that can be taken to reduce out-of-stocks, addressing the various points and eliminating the corresponding causes. For example, automating OOS detection and replenishment together provides a holistic solution for reducing the OOS rate.

Summary: Out-of-Stock

Out-of-Stock describes the unavailability of products that are expected or have already been priced from the customer’s point of view at the point of sale. Thanks to digitalization, the latter also includes online retailing – in other words, wherever the end consumer expects to find inventory but finds none. It is therefore the shortage of a product that is not available on a shelf space designated for it with a label or is not available in the expected condition. As a characteristic of listing differences, this also includes the de facto non-listing of a mandatory item agreed between the manufacturer and the retail headquarters. The disadvantage of such a situation is that if goods are not available, the customer often changes stores or decides on a different brand. That is why out-of-stocks are reduced, for example, by optimal shelf availability (OSA). However, a complete elimination does not make economic sense, since according to a decreasing marginal utility, the gained shelf availability does not bring any further benefit beyond a certain level.

*Listing differences is a familiar term in store logistics: an agreement between the manufacturer and the distribution center regarding the availability of certain items is not implemented or is delayed by a store. From a logistical point of view, there is no gap on the shelf, but from the customer’s point of view there is, because these items are expected and their non-availability causes similar reaction patterns as a real gap on the shelf.

Article image: Andrew Heneen / CC BY 4.0

If you are interested in the topic of store logistics, then read the articles on inventory management and stock keeping units.