nExtCOMbag®

Sustainable, automated packaging with kraft paper

Increase your planning reliability in personnel and capacity management with the fully automatic packaging solution, which can be integrated into your existing intralogistics in a space-saving and future-proof manner. Master order peaks and seasonal spikes in e-commerce.

ideas follow functions

The software manufactory principle: A tailor-made solution based on proven best practices

We have been at heart of the intralogistics market as planners and implementers since 1980, so we know that the most efficient solutions are as simple as possible and only as complex as necessary. Packaging in e-commerce poses many challenges for governments, companies and end consumers, that is why we are tackling this issue.

Local waste management companies and end consumers have to handle more and more cartons, while retailers depend on a pool of flexible labour, which leads to fluctuations in quality and throughput in the packaging process.

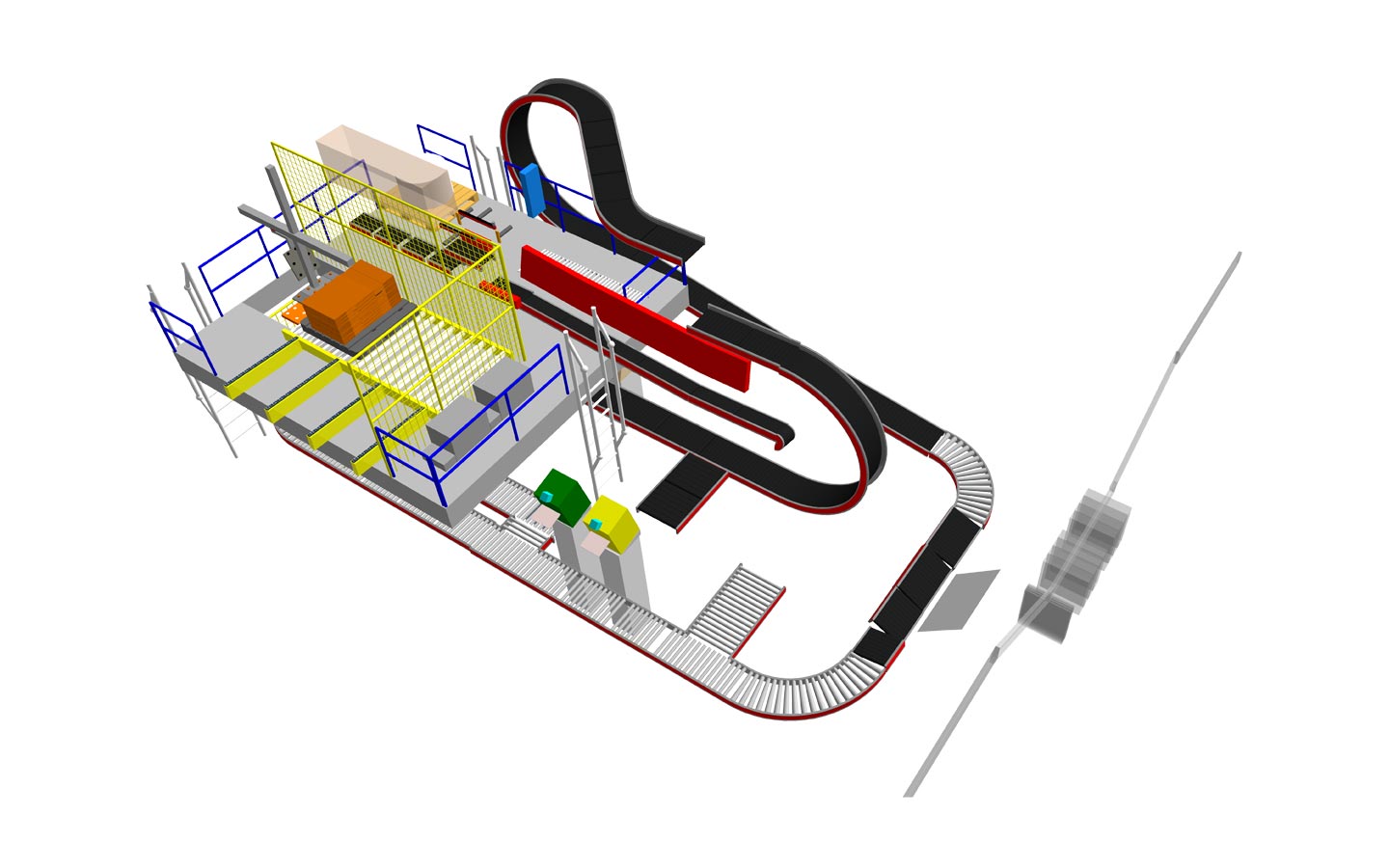

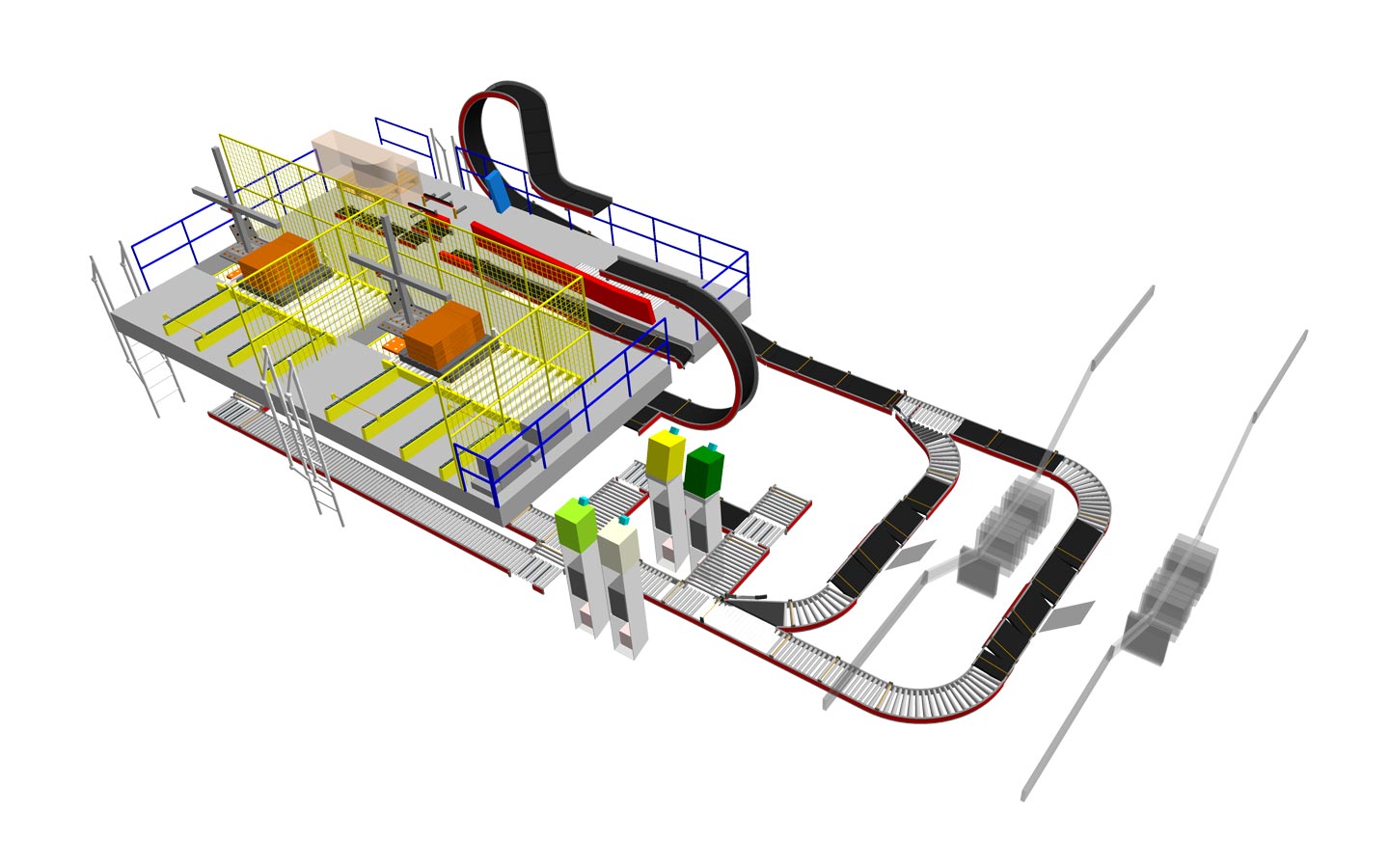

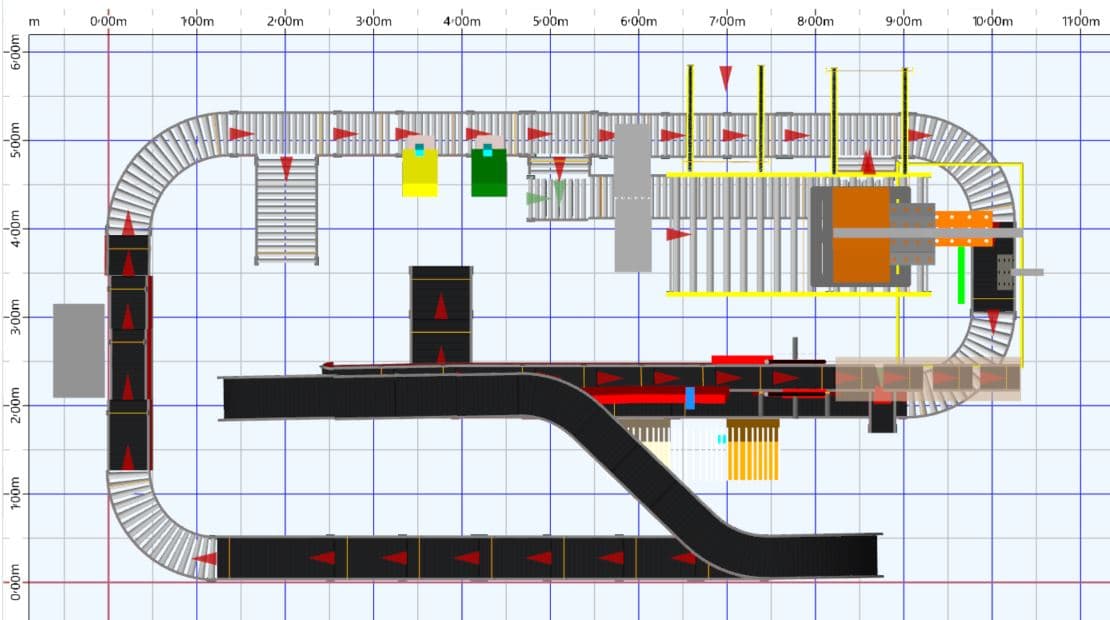

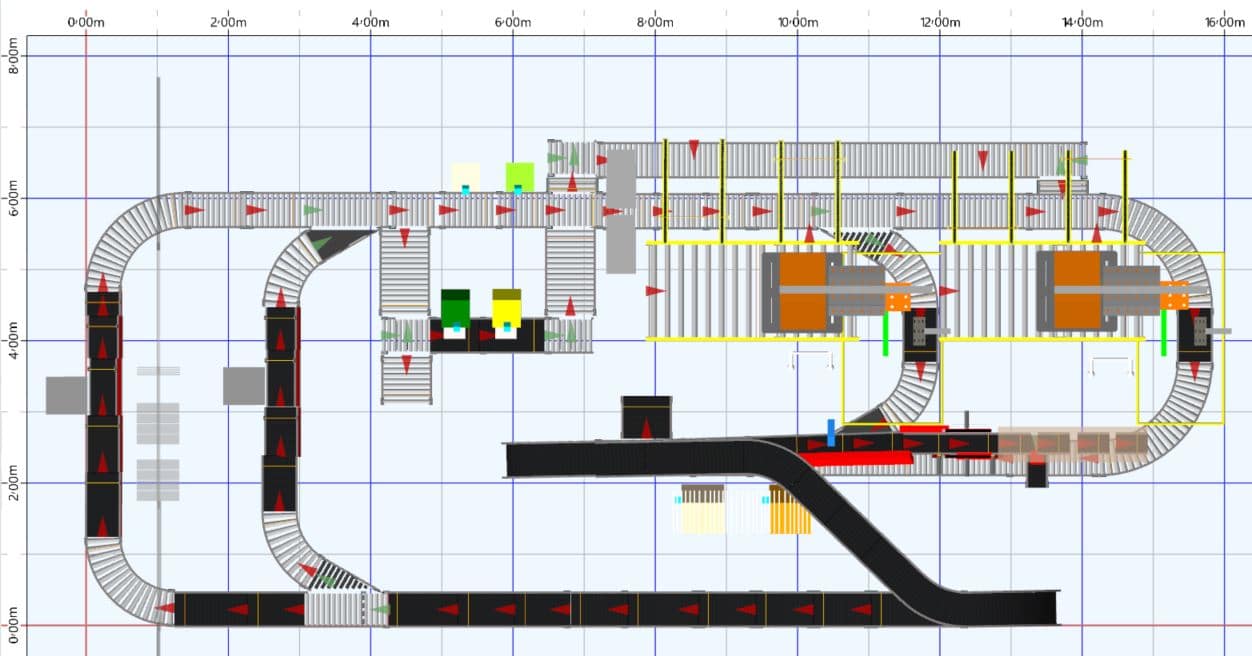

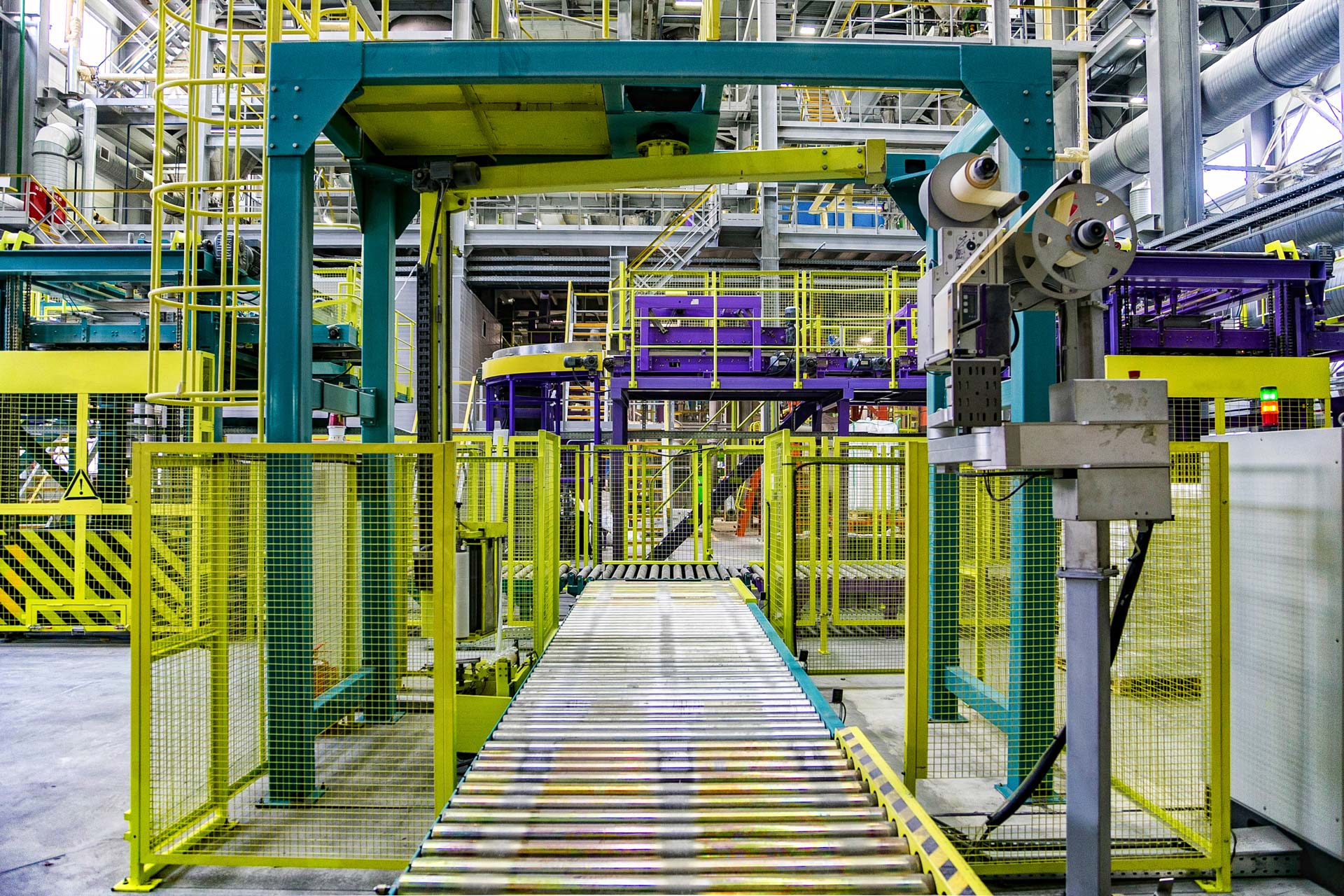

Our solution is nExtCOMbag: The answer to current e-commerce challenges based on kraft paper bags. It performs fully automatic packaging with the features sorting, filling, document management, packaging material handling, ‘intermarrying’ of containers and packaging, printing of shipping labels and the final volume-optimised sealing of single and multi-pos orders. In the design of nExtCOMbag, we place emphasis on compactness, modularity and the simplest possible conveying processes.

the advantages

An ideal process and an ideal material

- Flexible loading via fully automatic process steps

- Dynamic demand with a performance flexibility factor of 5

- Variable throughputs from 1,800 articles (one module) to 9,000 articles (5 modules) per hour

- For 1,125 to 5,625 orders per hour only a handful of employees are needed – part-time employees on call become a thing of the past

- Return on Investment (ROI): We openly claim that the investment will pay for itself after one year or less than five years

Economic, sustainable and end customer-friendly e-commerce logistics

Due to the high variance in size and combination of the ordered goods, the packaging of this variety of products is difficult to automate. Well-packed goods are a unique selling point to stand out from the competition. In addition, the avoidance of surplus and unused volume creates more efficiency in the logistics processes.

Our technology, including kraft paper bags, enables fully automated processing. This saves money, is environmentally friendly and, thanks to a uniform packaging design with integrated resealability, is also particularly end-customer-friendly.

Your contact

Our sales manager Swen Weidenhammer is a specialist in combining automation solutions with modern information technology.

The nExtCOMbag modules

We have designed the system in two versions: Compact and Basic. At 60m², the Compact version can be easily integrated into existing brown field scenarios and can handle 600 orders per hour. The Basic version requires 154m² and can handle 1125 orders per hour.

- Items per hour: 960

- Orders per hour: 600

- Personnel required: 1,48

- ROI: < 1 year

- Investment: 1,1 million €

- Cost of kraft paper bag: 20 ct

- Space requirement: 60m²

- Items per hour: 1800

- Orders per hour: 1125

- Personnel required: 2,71

- ROI: < 2 Years

- Investment: 1,4 million €

- Cost of kraft paper bag: 20 ct

- Space requirement: 112m²