The material flow control system (MFCS) or material flow controller (MFC) is often described as an order management system that is directly assigned to a materials handling system. However, this general definition of material flow control no longer does justice to the actual task if a logistics center has a heterogeneous structure of materials handling equipment that has grown over time and needs to be precisely coordinated to achieve optimal operating results.

In the world of IT systems for logistics centers, material flow control plays a central role. Despite a large number of different facilities and expansion stages, it must ensure maximum throughput of the facility at all times. In doing so, it must be predictable and stable in its behavior, yet adaptable to new strategies, expanded facilities and new ideas at any time during the runtime.

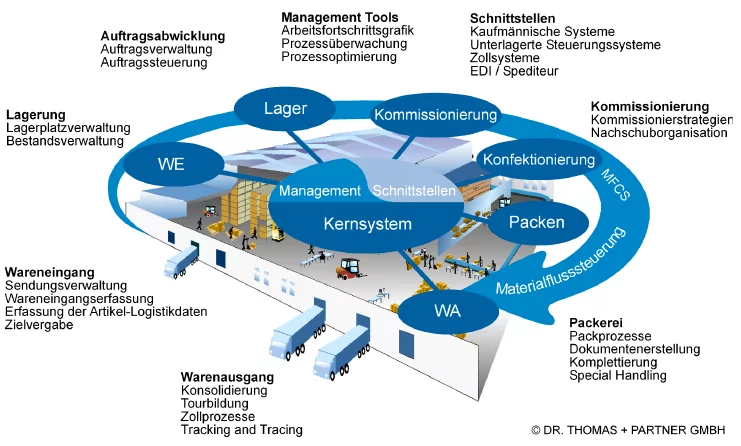

Warehouse management – the tasks of a warehouse management system, including material flow control

The primary task of material flow control is to perfectly coordinate transport tasks and transport orders of the connected systems. The available means of conveyance must be assigned transport orders and utilized to capacity – without the facility being blocked. At the same time, the operating status of the facility and the occupancy status of routes, points and transport resources must be taken into account at all times.

In particular, when coordinating transport, the load situation of all conveyor areas must be taken into account together.

For example, the often-encountered constellation of a forklift traffic area with a pallet conveyor system and an automatic high-bay warehouse must be controlled together.

You can find more information about material flow in our articles.

Image sources: TUP