TUP.WMS

Warehouse management - as simple as possible, as complex as necessary

Our WMS offers you an individually tailored, lean and process-oriented warehouse management. Due to the adaptive software TUP.WMS can be modularly designed and rapidly developed.

software follows function

How the software manufactory creates customer-centric and individual solutions with standardized tools

The user of applications within intralogistics is always faced with this challenge: What to pick? A standardized or individual solution? The standard solution may initially appear to be reasonably priced, but covers the required processes only to a limited extent. Anyone who wants to adapt quickly and effectively to changes in their customers’ markets and has recognized the competitive advantage of logistics will want to implement their knowledge and objectives both now and in the future. An individual solution offers this advantage because it is as simple as possible and as complex as necessary.

As a company active in research, our principle of the software manufactory combines the highest flexibility with the greatest possible security. Since we follow the guideline “software follows function” as a basis for your business processes, the TUP.WMS can completely map your warehouse. This applies to all manual processes as well as to development stages with the highest level of automation and all warehouse technologies. TUP has been active in the market since 1980, providing consultation and carrying out research to find the best solution. In addition to our experience, we have a wide repertoire of market proven best practice building blocks that we can apply to your individual requirements and functions. Here you can learn more about our approach to green and brown field projects.

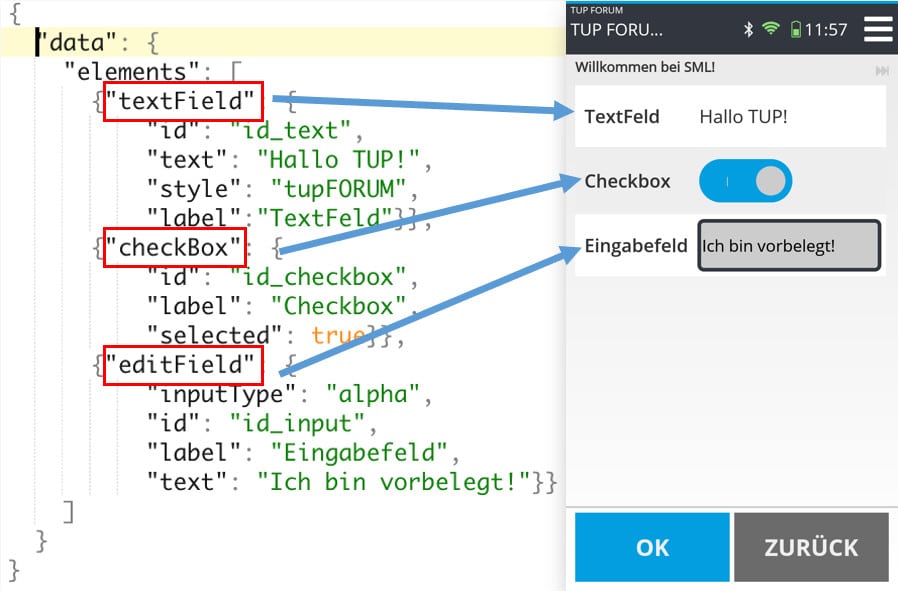

In order to accompany your processes in the best possible way, we rely on standardized tools that enable us to efficiently meet your individual requirements.

the advantages

Your intralogistics solution at a glance

- Smooth process flow from goods receipt to goods issue with very stable system behaviour and great versatility

- Combination of different picking forms for efficient order processing

- Transparency of all stock movements and order throughput

- Comprehensive control center functions for effective planning, monitoring, control and optimization of business processes

- Minimization of logistics unit costs through economic processes

- You can rely on a tried and tested system that has won several top-class awards and is adaptable, expandable, future-proof

The TUP.WMS

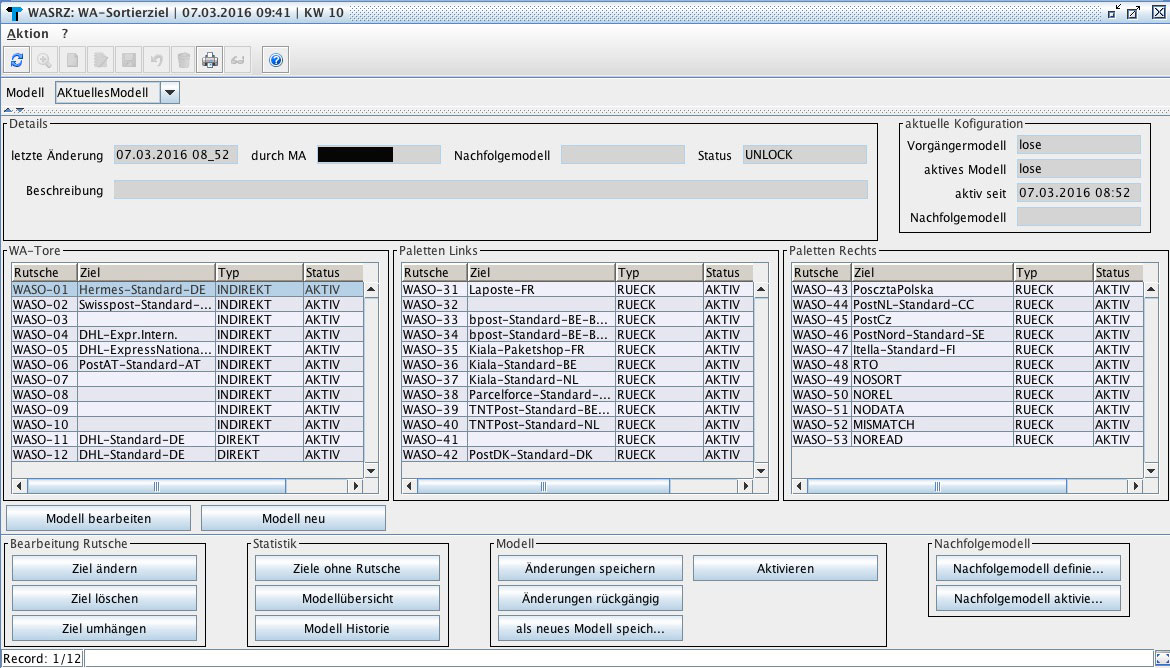

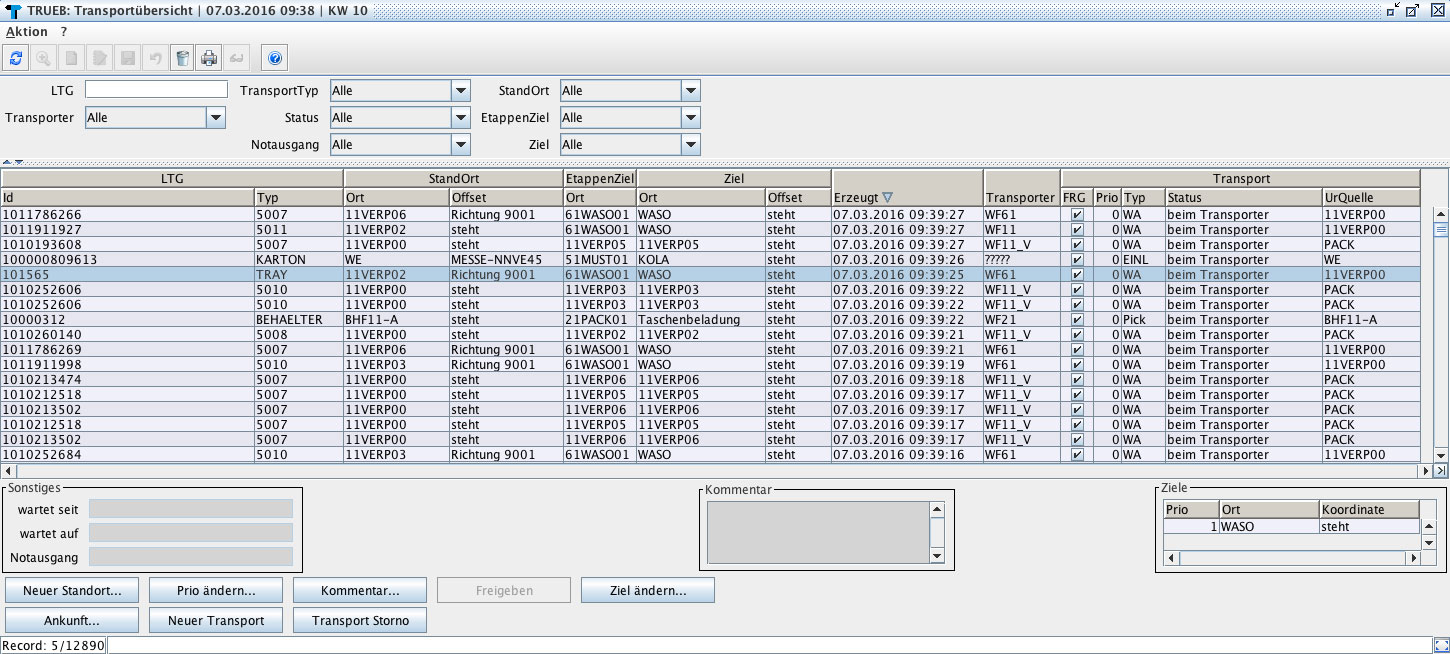

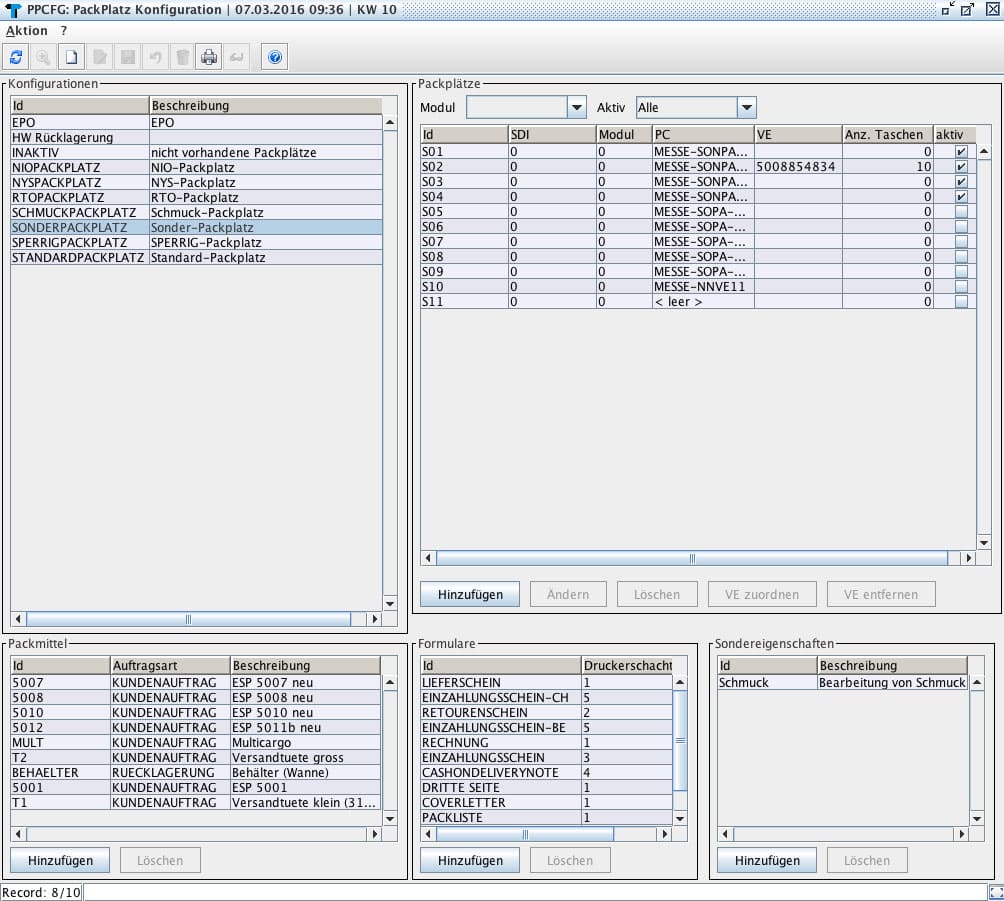

Graphical User Interface - Gallery

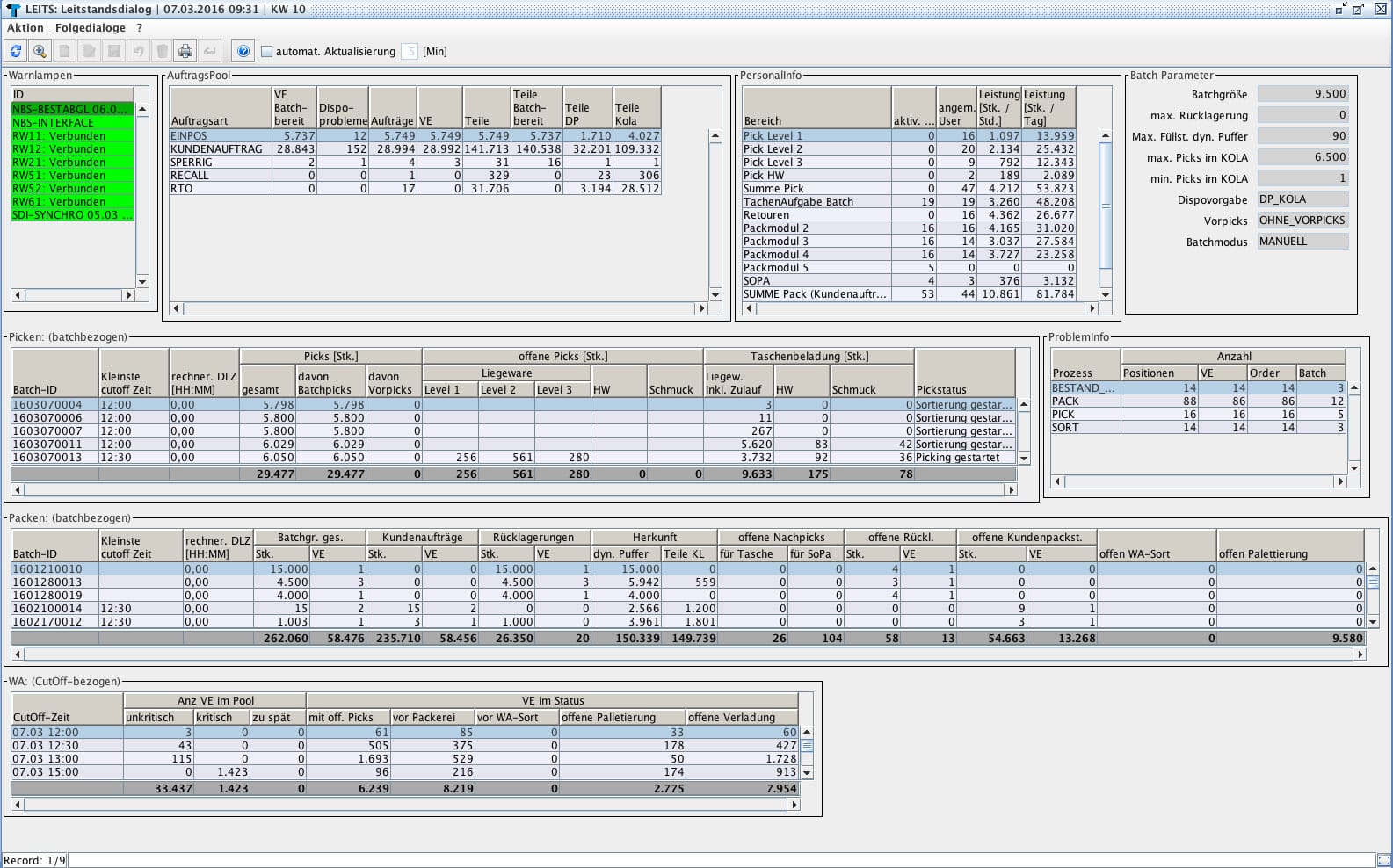

Control station dialog

The user gets details about the status of the respective batch, picks and can view the packing station. In addition, the user sees the cut-off times as well as the work performance of the personnel and the open processes in the order pool. Customized notifications for system parameters improve the response time in critical situations.

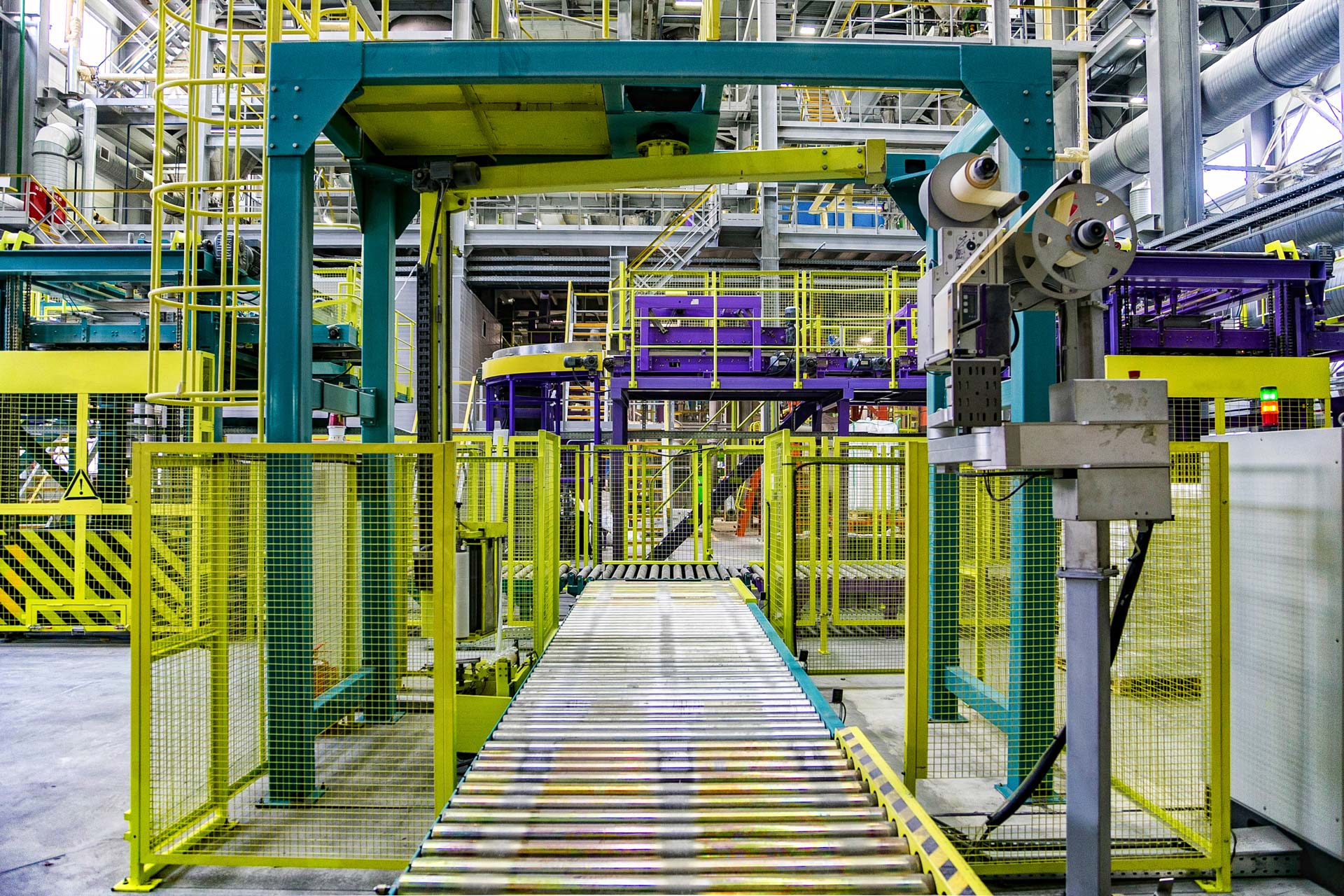

Combine future-proof innovation with tried and tested standards for your intralogistics

Within intralogistics, basic processes appear similar, but depending on the business process, different requirements are applied to them. Therefore we have developed our TUP.WMS as a modular IT system: On a standard platform with basic services we build IT modules that are specifically tailored to your individual intralogistics needs. From goods receipt to storage, picking, packing, packing and dispatch, everything is designed to turn your processes into a competitive advantage.

Extensions, adjustments or the integration of a new location abroad at a later date are at all times possible. This is where your economic advantage is: You only acquire what you actually need. The standardized and proven components also guarantee a high degree of reusability and easy adaptation for future extensions.

Success Story

Central distribution center of Grass GmbH in Hohenems

TUP developed an individually tailored Warehouse Management System (TUP.WMS) with an integrated Warehouse Control System (TUP.MFC).

Warehouse management by TUP - TUP.WMS

The TUP.WMS is the core of the TUP portfolio and provides best practices for all processes, from goods receipt, storage and picking to goods issue. Discover the advantages for your intralogistics.

Efficiency increase for your warehouse

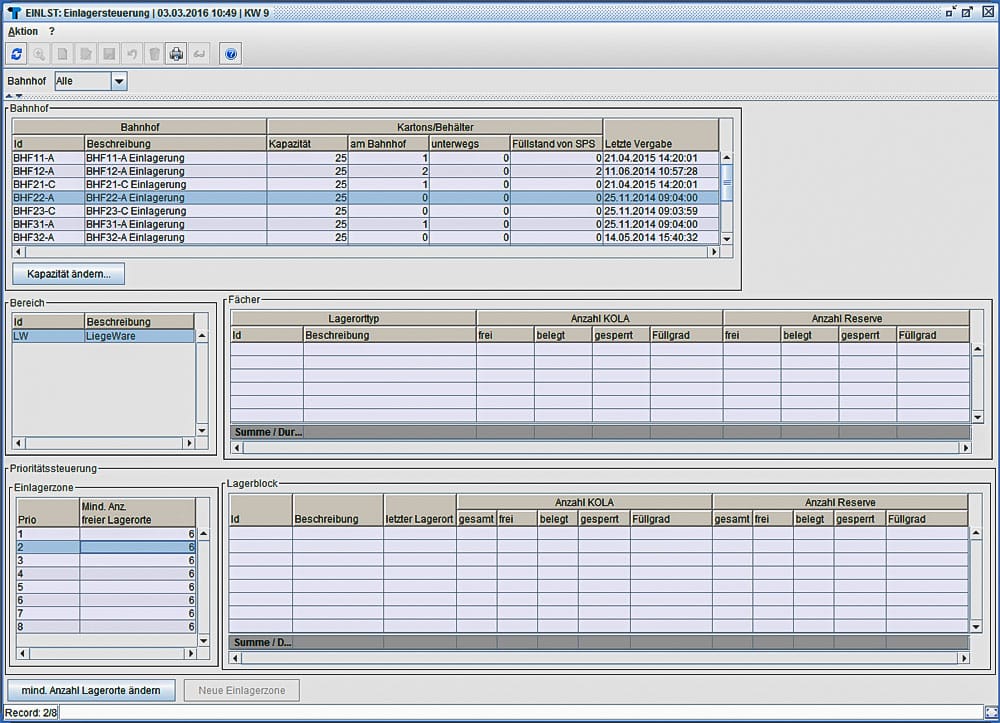

Unused storage space wastes potential, too little storage space reduces the throughput and endangers the objectives of your logistics. Therefore the choice of warehouse size and strategy is crucial for your success. TUP.WMS offers you the possibility to design your warehouse in such a way that you achieve these goals.

Ways of warehouse configuration

Control your shelf management according to the fixed space principle, via dynamic assignment or with flexible shelf allocation by your employees. The TUP.WMS supports manual as well as automatic storage and retrieval, ABC storage and storage in batches. Use flexible replenishment strategies in your picking, such as Kanban stock removal, precautionary or statistical replenishment. Define criteria for quality changes or the implementation of quality blocks. Single- or double-deep storage is also integrated.

All common storage types are supported, such as shelf storage, pallet storage, high-bay storage or automatic small parts storage. In addition, the warehouse management software can control paternosters, automatic carton warehouses with optimized travel paths and many other solutions.

storage strategies

Stock transfers between warehouses, locations, bins and containers can be tracked in the system based on status, even when parts of a pallet are compressed or transferred. If required, TUP.WMS also performs automatically generated stock transfers for storage bin optimisation in both manual and automatic warehouses.

blocks>/strong>

Blocks can be defined based on the location parameter, such as location, storage location, storage zone, storage bin. In addition, object-based properties can be used, such as load carrier, item, batch, serial number, delivery, order or order item.

Inventory

TUP.WMS supports the inventory in the entire warehouse, in a storage section or in a storage bin. The process can be limited to one article or one period. If necessary, the system blocks the elements that are to be inventoried. Documentation is provided via count and difference lists or a continuous automatic inventory.

Management of goods receipt

The goods receipt is at the beginning of the process chain in the warehouse. The data recorded here is the basis for further processes. Their accuracy therefore determines the quality of all subsequent processes.

data acquisition

All relevant information is recorded in the necessary quality: carriers, vehicle data, delivery dates and times and much more. The type of recording can be defined in detail: Shipment recording with or without advice note, recording of serial/batch numbers, expiry dates or allocation to individual, partial or complete deliveries and more are possible. The data can be entered automatically or manually at identification points.

Monitoring und Steuerung

carriers, vehicle data, delivery dates and times and much more. The type of recording can be defined in detail: Shipment recording with or without advice note, recording of serial/batch numbers, expiry dates or allocation to individual, partial or complete deliveries and more are possible. The data can be entered automatically or manually at identification points.

Monitoring and control

Delivery dates, quantities, goods, quality, shortfalls or overruns are monitored via the notification and delivery monitoring system. This simplifies quality assurance and plausibility checks in clarification case processing.

The control is carried out by automatic or manual target assignment with various flexible and parameterizable putaway strategies. The following parameters are used: logistical master data, physical parameters of the storage bins, assignment of the articles to storage groups or zones based on prioritisations such as ABC distribution or in the article master of defined storage structure. For a possible granular control, areas can be marked as buffers or with a putaway block.

The TUP.WMS generates the transfer orders for the material flow computer or manual process steps. It supports all processes via various interfaces. Internal and external returns are also covered by the process control.

Labels and documentation

Goods receipt documents of any kind can be printed out automatically or manually: LE-, LTG-labels, barcodes, storage aids or customs declarations.

Picking requirements

Order picking is the heart of your distribution center. That’s why we first want to understand your structures and requirements before we implement your custom-fit order picking system. The efficiency of this system has a decisive influence on reaction time and costs, the key figures for the success of your intralogistics. Route optimization is therefore the top priority, as order picking involves many manual processes.

Supported picking types

One to three-step picking as well as manual sort picking is possible. The system supports pallet or single part picking and batch processing. Golden carton and outer carton picking are available as special forms. The staging forms ‘pick-pack’, ‘person to goods’ and ‘goods to person’ can thus be mapped with higher efficiency. Adapted processes for promotion goods or ‘Value Added Services’ are also part of TUP.WMS.

Control

Üare monitored via advice notes and delivery monitoring. This simplifies quality assurance and plausibility checks in clarification case processing.

The control is carried out by automatic or manual target assignments with various flexible and parameterizable putaway strategies. The following parameters are used: logistical master data, physical parameters of the storage bins, assignment of the articles to storage groups or zones based on prioritisations such as ABC distribution or storage structure defined in the article master. For a possible granular control, areas can be marked as buffers or with a putaway block.

The WMS generates the transfer orders for the material flow computer or manual process steps. It supports MDE-guided processes via various interfaces, such as WLAN. Internal and external returns are also covered by the process control.

Labels and documentation

Goods receipt documents of any kind can be printed out automatically or manually: LE-, LTG-labels, barcodes, storage aids or customs declarations.

More efficiency and flexibility for your outgoing goods

Consolidate packages from the different processes in the outgoing goods area, adapted to the carrier, outgoing relations, variety of goods and cut-off time.

Consolidation>/strong>

Using TUP.WMS you can merge single shipments parameter-controlled, compile the goods of a customer order and cluster the orders by country, shipping type or tours. Cross-docking as an efficiency-enhancing measure is also supported.

Tour formation

The system supports you in putting together tours and helps you to use the optimum volumes depending on the type of loading, for example via parcel services or forwarding agents.

Monitoring>/strong>

Gain a quick overview of the relevant key figures of your outgoing goods and track your deliveries via tracking connections after dispatch.

Export and customs clearance

With TUP.WMS you can maintain your customs tariffs and print the necessary customs documents for export goods. Interfaces are also integrated for data transfer to the customs system.

Your contact

You have a project enquiry or want individual consultation on TUP.WMS?

Our sales manager Swen Weidenhammer is a specialist in combining automation solutions with modern information technology.