TUP.MSF

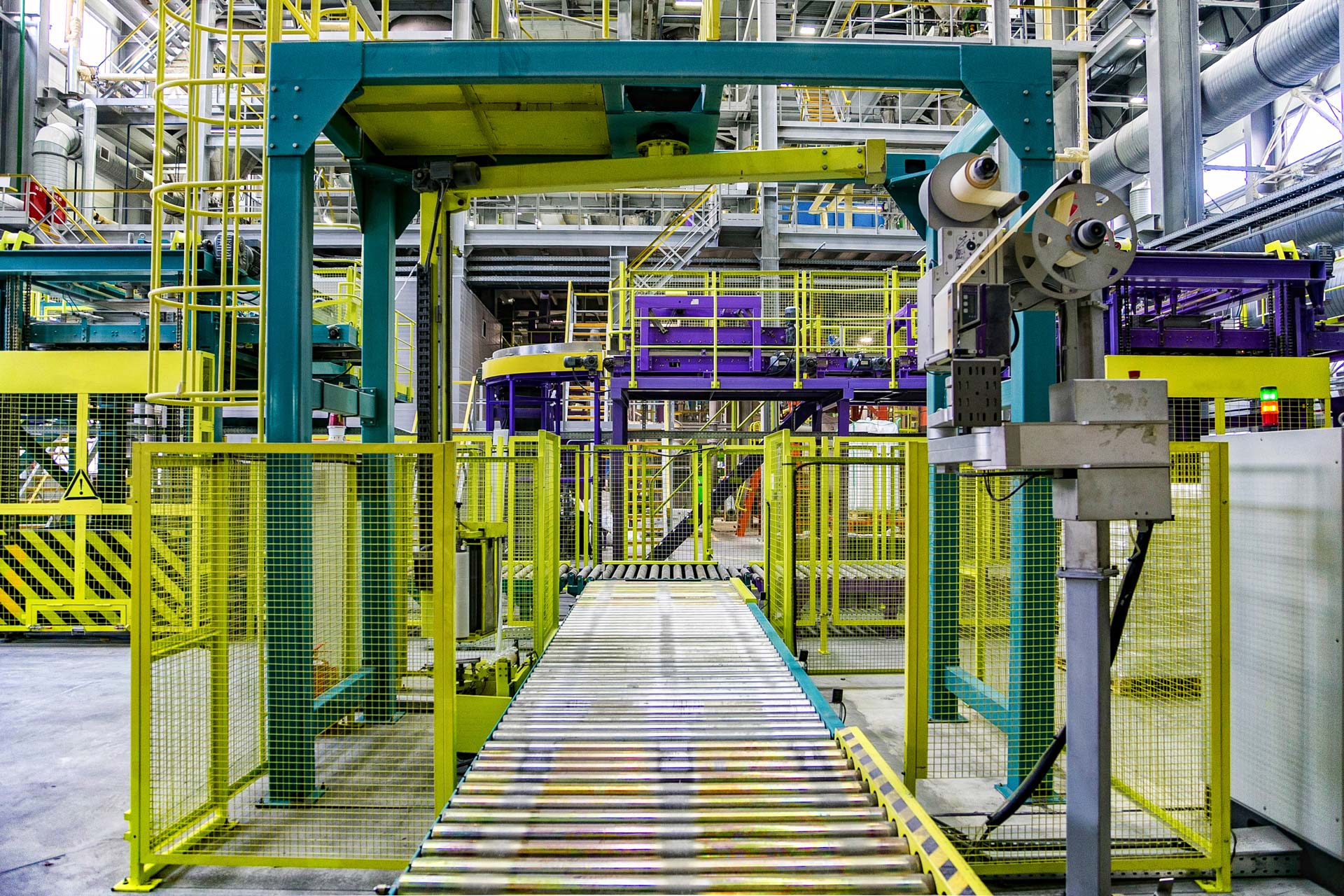

Manual picking at the performance level of an automatic sorter

Heterogeneous article ranges and strong seasonal fluctuations in demand require a flexible solution that enables economic capacity utilisation. With our manual sort order picking, the individual work steps become a transparent process, from picking to packing. This gives you planning reliability and allows you to deploy your employees where there is a need.

software follows function

How the software manufactory principle makes your order picking more flexible and cost-effective

In order to turn order picking into a clear competitive advantage, market-proven, standardized processes are needed that are adapted to the individual conditions of the location. This is the only way to ensure that the routes are actually the shortest and that personnel bottlenecks are recognized and compensated for in good time.

Due to our experience in the market since 1980, we know the potential of IT-supported manual sort order picking and integrate new technologies seamlessly into our adaptive software.

In this way, we create scalability without losing flexibility and guarantee a smooth workflow with a more even workload for the employees. Especially for companies with heterogeneous articles or a warehouse topology that is difficult to automate, the TUP.MSF offers the possibility of raising optimisation potentials in a cost-effective and sustainable way.

Find out more about our consulting services in intralogistics design.

The advantages

The manual sort order picking at a glance

- Highest possible flexibility for fluctuating order volumes

- Increased employee motivation through varied workflows with more even workload

- Cost-effective, flexible scalability

- Optimal utilization of your intralogistics

- Performance, throughput and quality of a fully automatic sorter

- Lower fixed costs and better ecological balance compared to automated solutions

The TUP.MSF

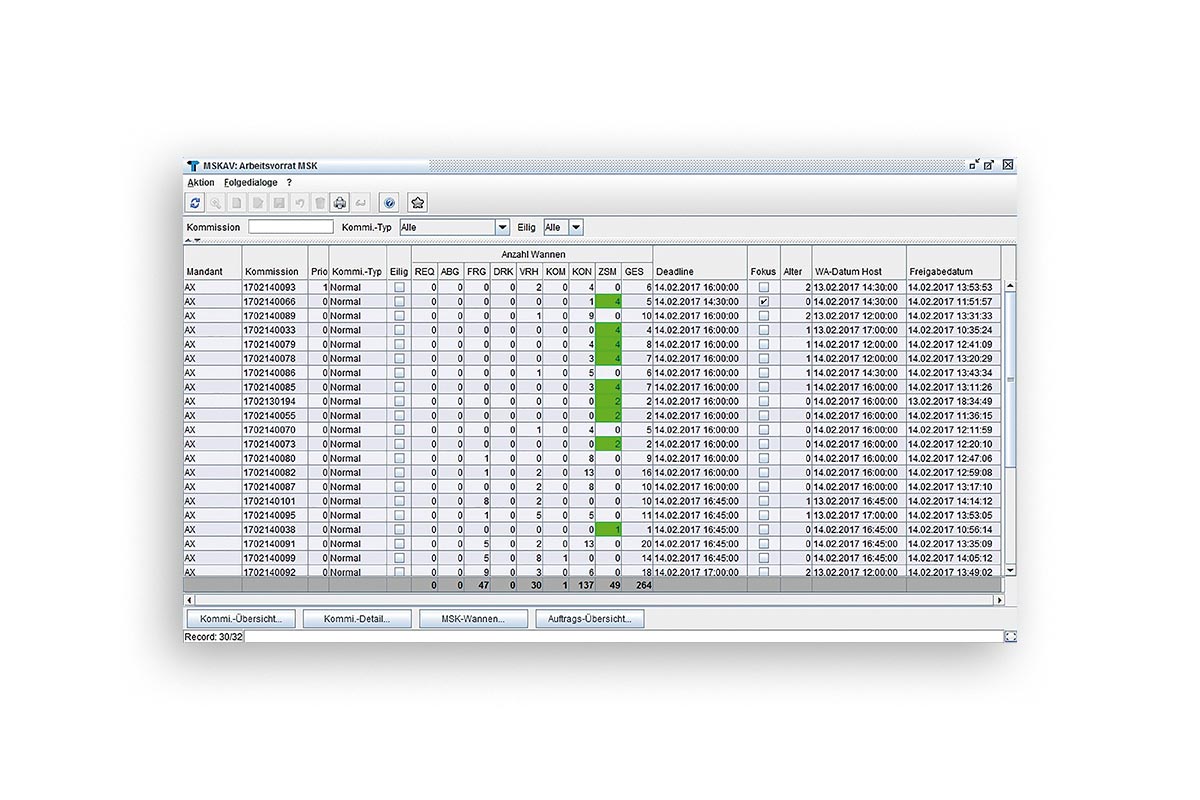

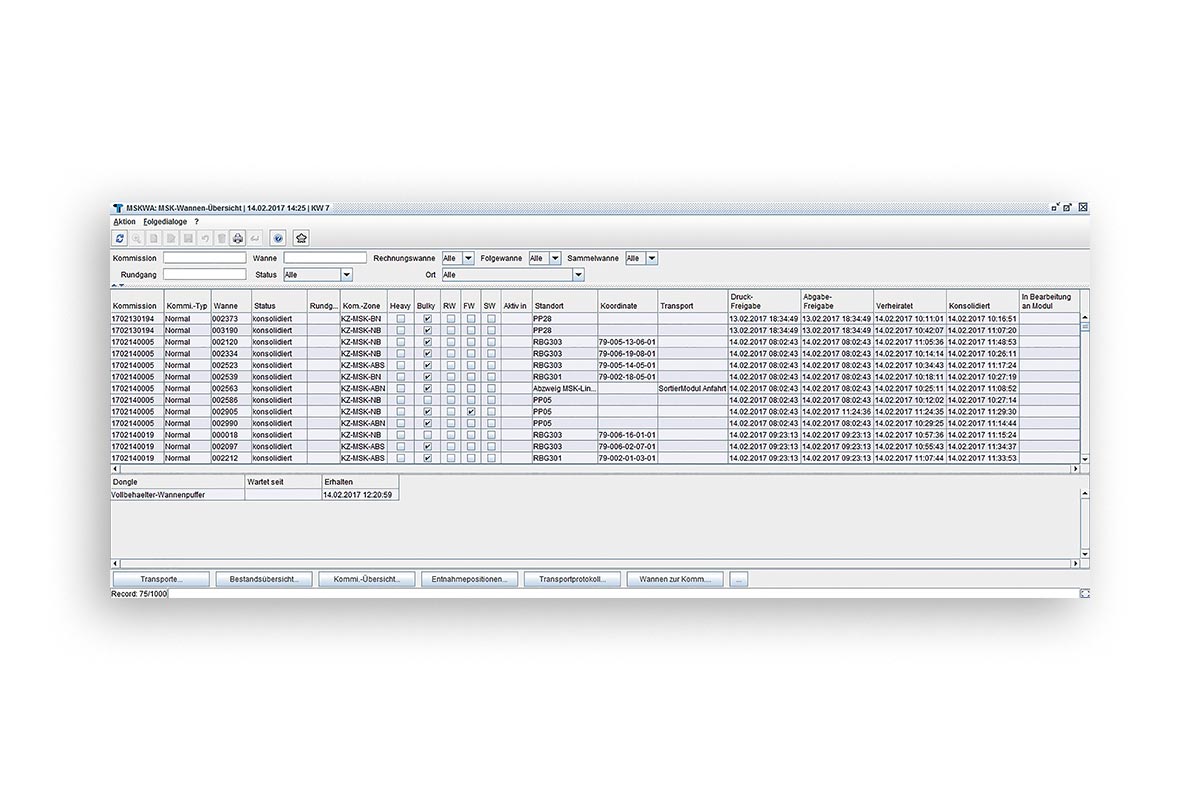

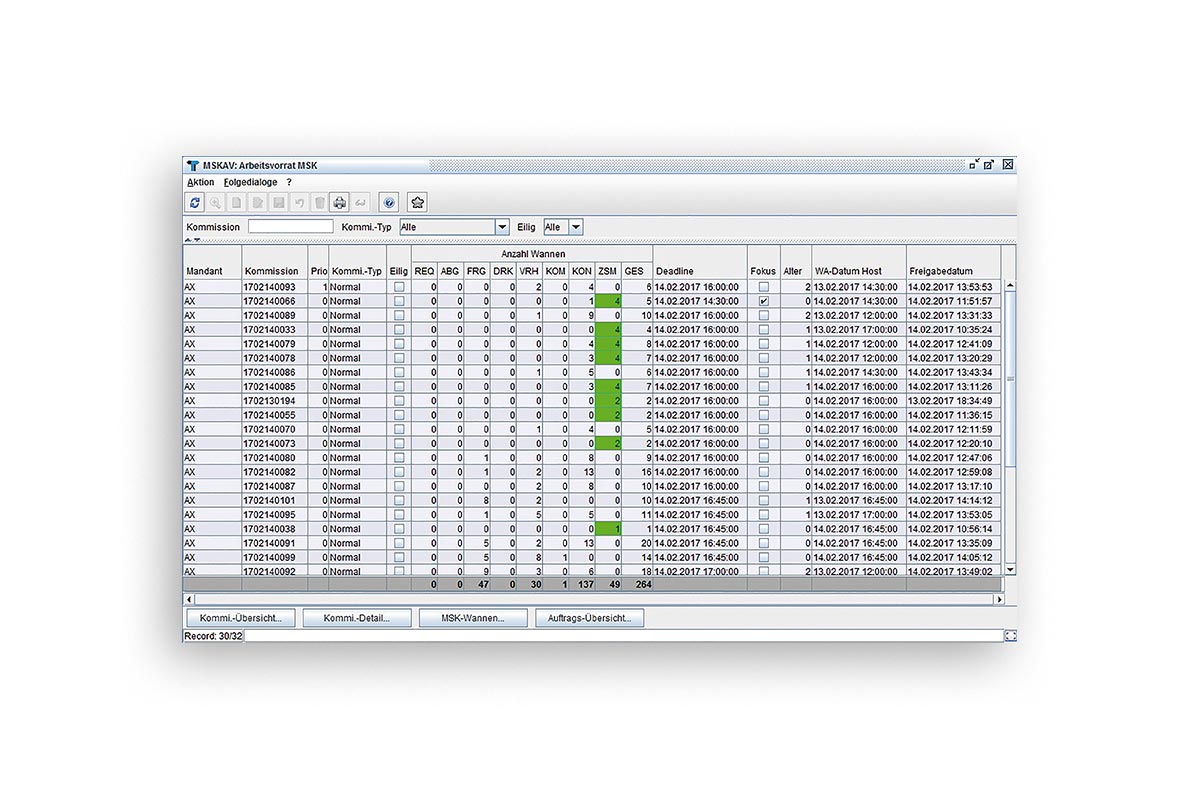

User interfaces of the TUP.MSF

Adaptive, intelligent software as a competitive advantage

Our motto is “First simplify, then automate”. When it comes to pushing a logistics center to its performance limits without investing massively in infrastructure measures, standard solutions often cannot deliver this last quantum.

Our experience is that above a certain size, certain scaling effects can only be achieved through individual solutions. A very precise knowledge of the respective business processes and the developments in the intralogistics industry is therefore a prerequisite for optimizing multi-stage order picking using software-supported sorting.

Success Story

Optimised walking routes at HABA

In order to achieve further optimisations in the order picking logistics of the Habermaaß Group, TUP has carried out a reservation optimisation with the RES program module of TUP.MSF.

Feature Overview - TUP.MSF

The TUP.MSF is our flexible solution for heterogeneous articles, seasonal fluctuations in demand and scaling requirements with the least possible infrastructural adjustments.

Features to improve your manual picking

Bottlenecks and intransparent material flows cause frustration in the workforce and avoidable costs. The TUP.MSF provides remedy by transparent material flows, batch formation and more even load distribution.

Application area with the highest added value potential

TUP’s manual sort order picking is ideally suited for companies with heterogeneous article ranges and strong seasonal fluctuations in demand. It achieves the performance, throughput and quality of a fully automatic sorter, with greater flexibility through variable personnel deployment.

Optimized workflows

At a control station, the workload and personnel availability are monitored at all times. Thus, the employees are sent to where they are needed. A work quota is defined for each picking instance. Threshold value settings enable individual control and thus ensure flexibility and profitability of the processes.

Transparent material flow

The article data is reported back to the stock management system after dispatching. In this way, invoices for the orders can be prepared in advance. It is known which commission contains which order and in which sorting pit the order will end up. The entire material flow is transparent, even without fully automatic goods recording.

Short routes

TUP.MSF enables a drastic shortening of picking routes. The investment in a sorter packing station is not necessary. In this way a flexible deployment of employees is possible, which can be controlled depending on order requirements.

Picking batches increase throughput

Orders are separated upon receipt into picking types that are based on the requirements of the respective order. This ensures optimal capacity utilization. The orders are combined into picking batches and then sorted again by order in the sorting packing department. As many orders as possible are included in a batch. The capacity of the sorting modules is already taken into account when forming the commissions in order to avoid bottlenecks.

Your contact

You have a project enquiry or want individual consultation on TUP.WMS?

Our sales manager Swen Weidenhammer is a specialist in combining automation solutions with modern information technology.